Company

History of NABEL

1964

- Established as subcontracting maker of control

devices for consumer electronics production lines.

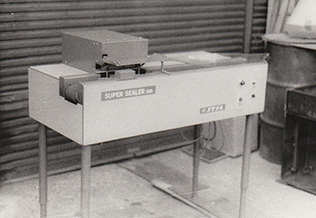

1975

- Announced first egg package sealer in Japan which utelized ultrasound vibration.Later gained 75% domestic market share.

1977

- Incorporation of Nambu Denki Co., Ltd.

1979

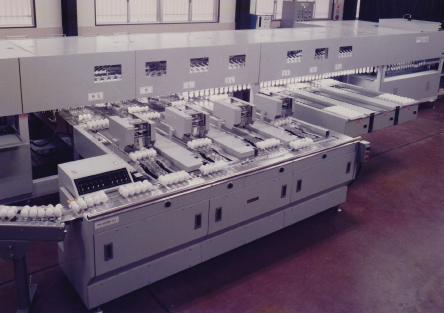

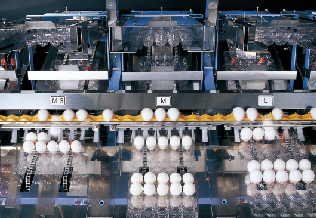

- Developed automatic egg grading and packing system. Developed control mechanism of transfer speed cancellation which dramatically reduced physical damage on eggs.

1984

- Announced semi-automatic candling unit which later contributed to quality control of egg production.

- Awarded Distinctive Invention Award from Science and Technology Agency.

1985

- Developed world’s first computer weighing system which enabled grading by fixed weight and volume.

1987

- Renamed as NABEL Co., Ltd.

1992

- Shipped the egg grading and packing system to Malaysia, which is the first unit delivered overseas.

1995

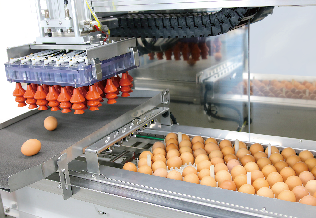

- Announced “NAEGS” series - World’s first robotic grading and packing system.

Acquired leading share in domestic market. - Announced stock-type tomato grading and packing system.

1997

- Announced “MAP” series - smaller scale grading and packing system.

- Recieved Kyoto Prefecture SME Technology Award for “NAEGS” series.

- Recieved Technology Award from Society of Agricultural Structures for stock-type tomato grading and packing system.

- Received the Excellent Technology Award from the Kyoto Industrial Technology Foundation for the robotic grading and packing system.

1998

- Announced “ACD” series - World’s first automatic crack detection system which applies Fourier Transform.

- Received highest award at 1998 Asian Pacific Poultry Congress.

- Received Distinctive Invention Award again since 1984 from Science and Technology Agency for stock-type tomato grading and packing system.

1999

- Relocated to Nagaokakyo.

- Announced large-scale grading and packing system capable of processing 60,000 eggs per hour with applied robotics technology “NAEGS”.

2000

- Announced “ABD” series for non-destructive automatic blood detection by spectroscopic analysis.

- Announced “ADD” series for automatic dirt detection by multi-light sourced image recognition.

- Become Kyoto Prefecture SME model factory.

2001

- Announced NARS - remote monitor system using public lines.

- Announced “Parallel Carrier” technology which enabled dramatic increase in production effeciency and demonstrated at international poultry show.

2002

- Announced stock-type grading and packing system. “SUPER NAEGS ORACION” with capacity of 60,000/120,000 eggs per hour.

2003

- Established subsidiary company in Malaysia.

2004

- Announced upgradeable “G-NAEGS” with single line capacity up to 40,000 eggs per hour.

2005

- First operation of Tower Stock system.

- Established maintenance office in Kariya, Aichi Prefecture.

2006

- Listed as one of 300 vibrant SMEs by Ministry of Economy, Trade and Industry.

2007

- Announced digital egg tester “DET6000”.

- President CEO Kunio Nambu awarded Intellectual Property Achievement Award by Minister of Economy, Trade and Industry.

2008

- Relocated to Minami-ward, Kyoto.

- Announced tape sealer “TES100/400”.

2009

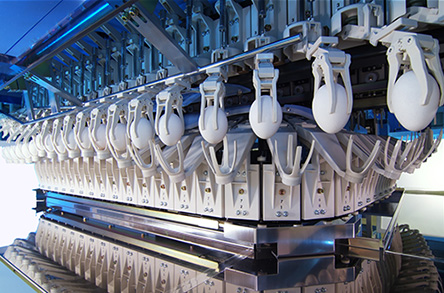

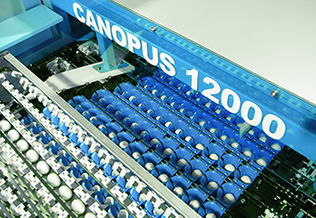

- Announced grading and packing system “CANOPUS”, designed to dramatically reduce physical impacts on eggs.

- Authorized as a "Kyoto Childcare Support Company" by Kyoto Prefecture.

2010

- President CEO Kunio Nambu received Award of Commissioner of Small Medium Enterprise Agency.

2012

- President Kunio Nambu appointed as CEO Chairman.

- Vice-President Tsutomu Maruyama appointed as President.

- Received Kyoto SME Technological Merit Award for ACD.

2013

- Announced farm packer of more compact type “FFP4100”.

- Announced grading and packing system “C-NAEGS” with carrier washing mechanism.

- Received 25th SME Technological Merit/New Product Award for EVS.

- Received Award of Minister of Economics, Trade and Industry at 5th Japan Manufacture Award for Tower Stock system.

2015

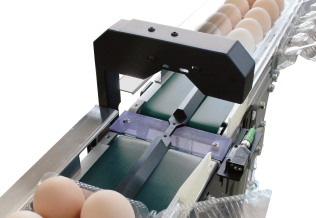

- Released the "pack egg checker", which detects abnormalities in packed eggs with only a 30mm gap between conveyors.

- Received 27th SME Technological Merit/New Product Award for Farm Packer.

- Received Science and Technology Award by Minister of Science and Technology for the development of detector for hatchery eggs with Vital signs.

2016

- Announced special label feeder ELS010.

2017

- Announced Case packer SMART Cube CP.

- President CEO Kunio Nambu awarded as person of industrial merit from Kyoto Prefecture's.

- Received 29th SME Technological Merit/New Product Award for Pack Egg Checker.

- Selected as a "Companies Driving Regional Growth" by Japan Ministry of Economy, Trade and Industry.

2018

- Kunihiko Nambu appointed as President CEO.

- Released the "pack all checker", which detects dirts, cracks, leaks and empty shells of eggs, and missing eggs in egg packages.

- Released the "pack in-label bar code checker", which detects abnormalities of internal labels and JAN codes of egg packages.

- Announced Case palletizer SMART Cube PL.

- Received the "Kyoto Future Town Planning Promotion Award".

2019年

- Released the "case destacker", which automates the supply of plastic crates to the production line.

- Released the "PaMaN" system, which manages eggs production information on the cloud with QR codes attached on pallets and racks.

- Received the "Kyoto City Shining Regional Enterprise Awards - Special Award".

2020年

- Released the "egg tray washer", which automates the washing and spin-drying of egg trays.

- Selected for the "Global Niche Top Companies Selection 100 list".

2021年

- Released the "CubeLink" system, which applies settings of dates, patterns, and parameters to all devices installed in the packing lines.

- Released the "neuron" system, which manages production information from egg grading floors and visualizes it as tables and graphs on the cloud.

- Released the "outer seal labeler", which automates the printing and application of labels to plastic packs.

2022年

- Released the "KENZO" system, which manages egg quality data measured by the Digital Egg Tester DET6500 and visualizes it as tables and graphs on the cloud.

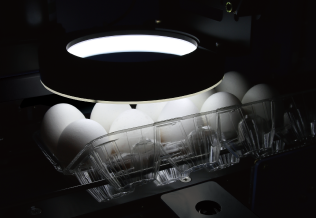

- Released the "embryonated egg inspector", which uses AI technology to determine whether developing eggs are suitable for vaccine production.

- Released the "pack final checker", which performs the final inspection of tape seals and labels on egg packages.

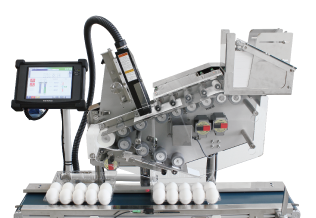

- Released the "pole auto dirt detector", which detects dirt on the pointed and blunt ends of eggs.

- Released the farm packer "Sakura" for overseas sales, compatible with water washing and various trays.

- I.P. Co., Ltd. became part of our group, and is the manufacturer of poultry incubators based in Tokushima.

2023年

- Released the "PI|Geon" system, which enables users to save and manage data of labels and stickers on egg packages.

- Released the "label checker", which detects the presence of labels in packs running on conveyor.

2024年

- Released the "mini-depalletizer", which automates the unloading of trays from pallets onto conveyors in small spaces.

- Released the "EGGMA" system, which centrally manages the entire process of eggs from receiving at factories as materials to shipping as final products.

2025年

- Released the "TOSAKA" system, which centrally manages poultry growth records.