Products

C-NAEGS Series

Grading

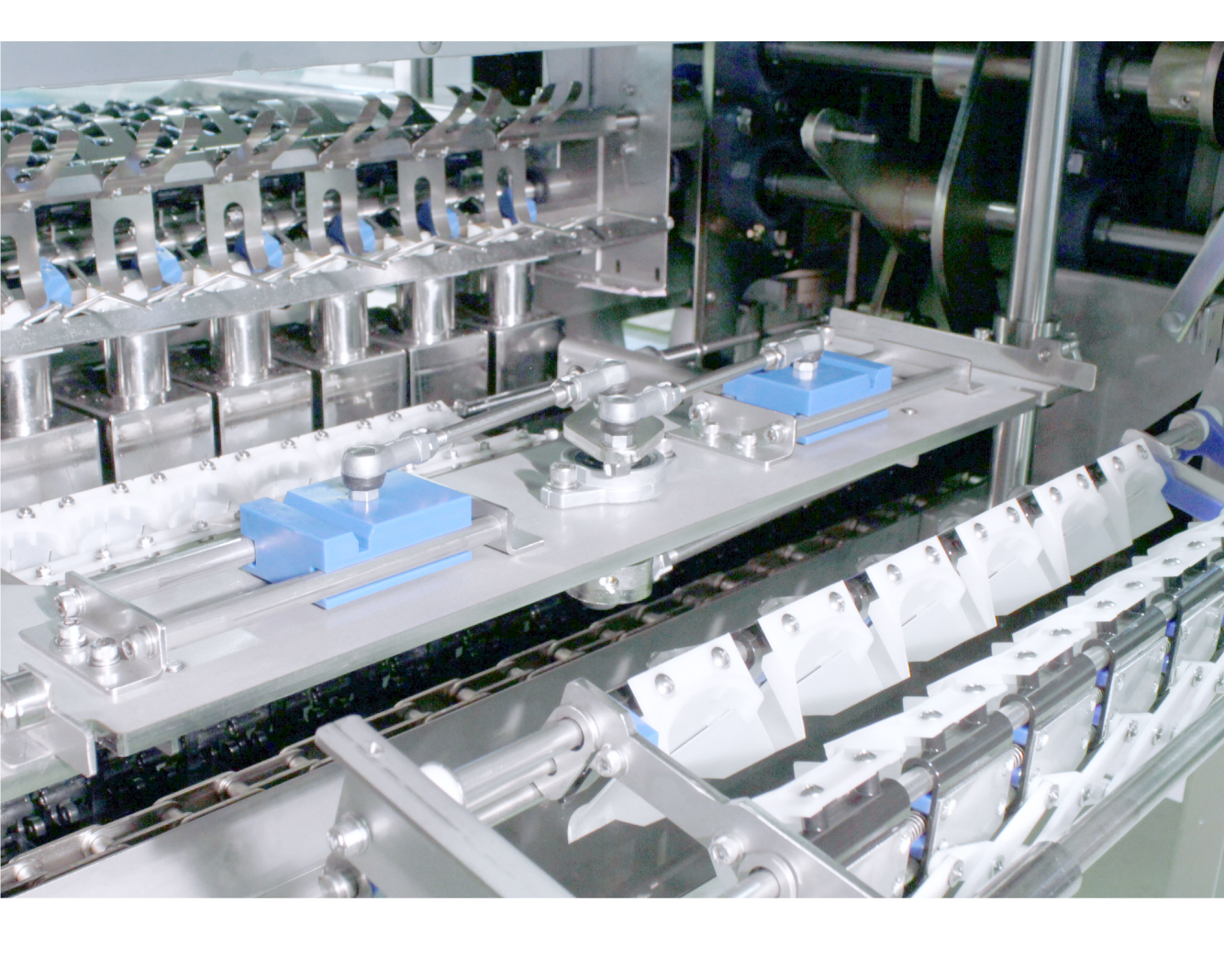

Our robotic system results in high levels of productivity

The main feature of our robotic system is the separation of the sorting and packaging processes. This means that a changeover or error will not cause the whole machine to stop, minimizing loss caused by non-operation.

Video

Features

High-mix, low-volume production

The machine is equipped as standard with two pack conveyors and one tray conveyor. It can pack eggs of different sizes at the same time.

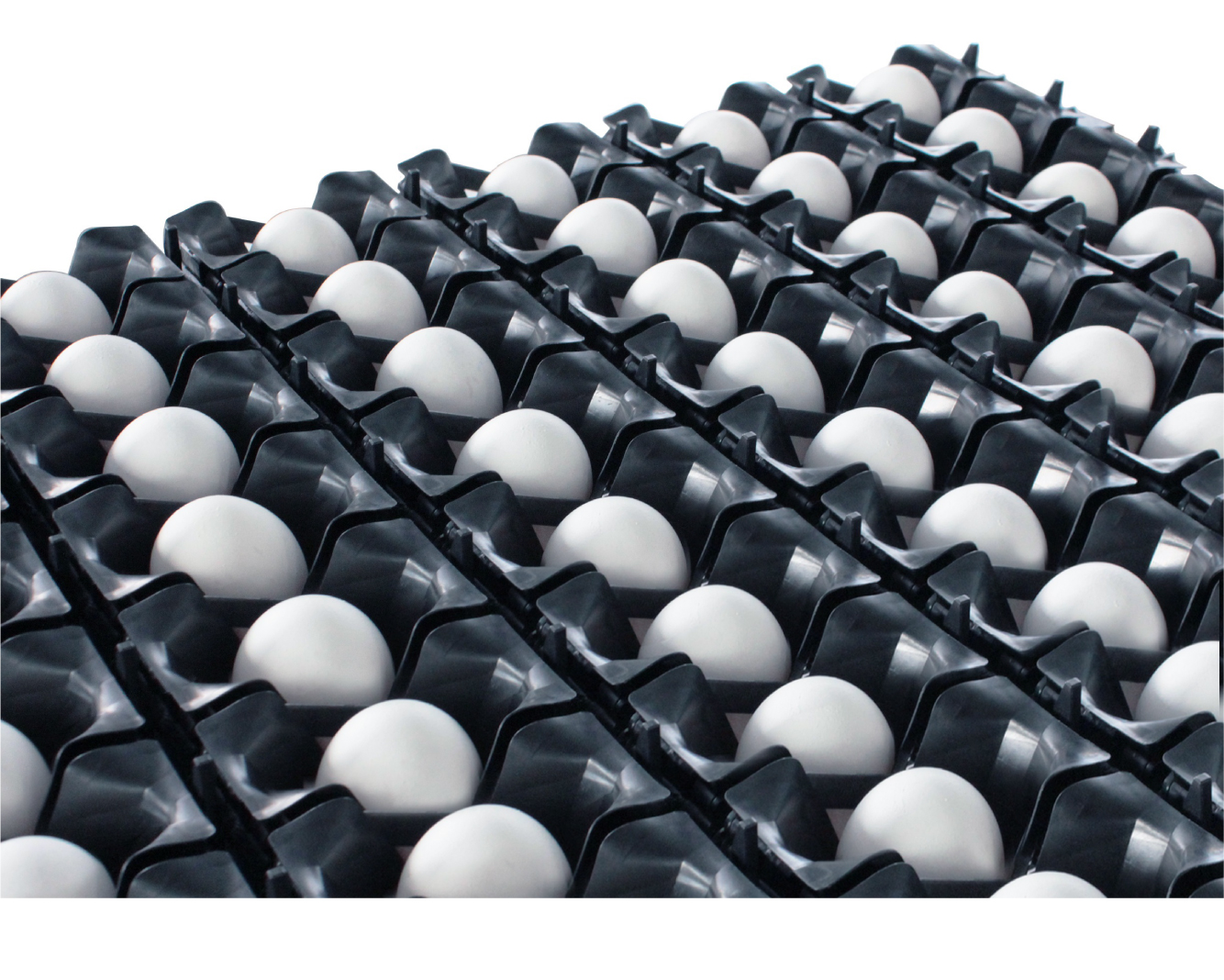

Narrow Pitch Carrier

Narrow Pitch Carrier moves slowly and process larger capacity. Since the carrier pitch is narrow, the carrier speed is suppressed, and the impact on the egg can be minimized.

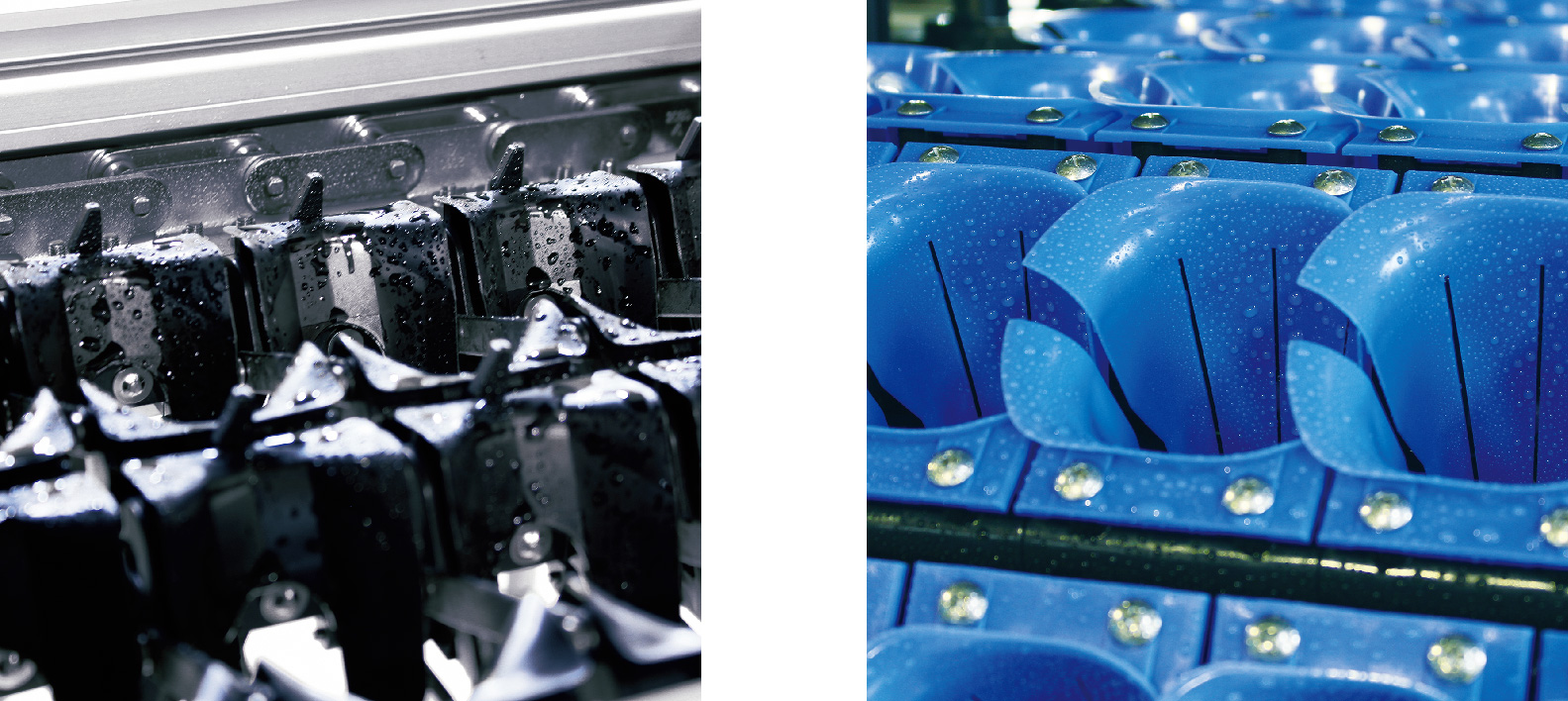

Made of stainless steel

The frame is made of stainless steel, which is resistant to rust and stains, making it durable and easy to clean.

Options

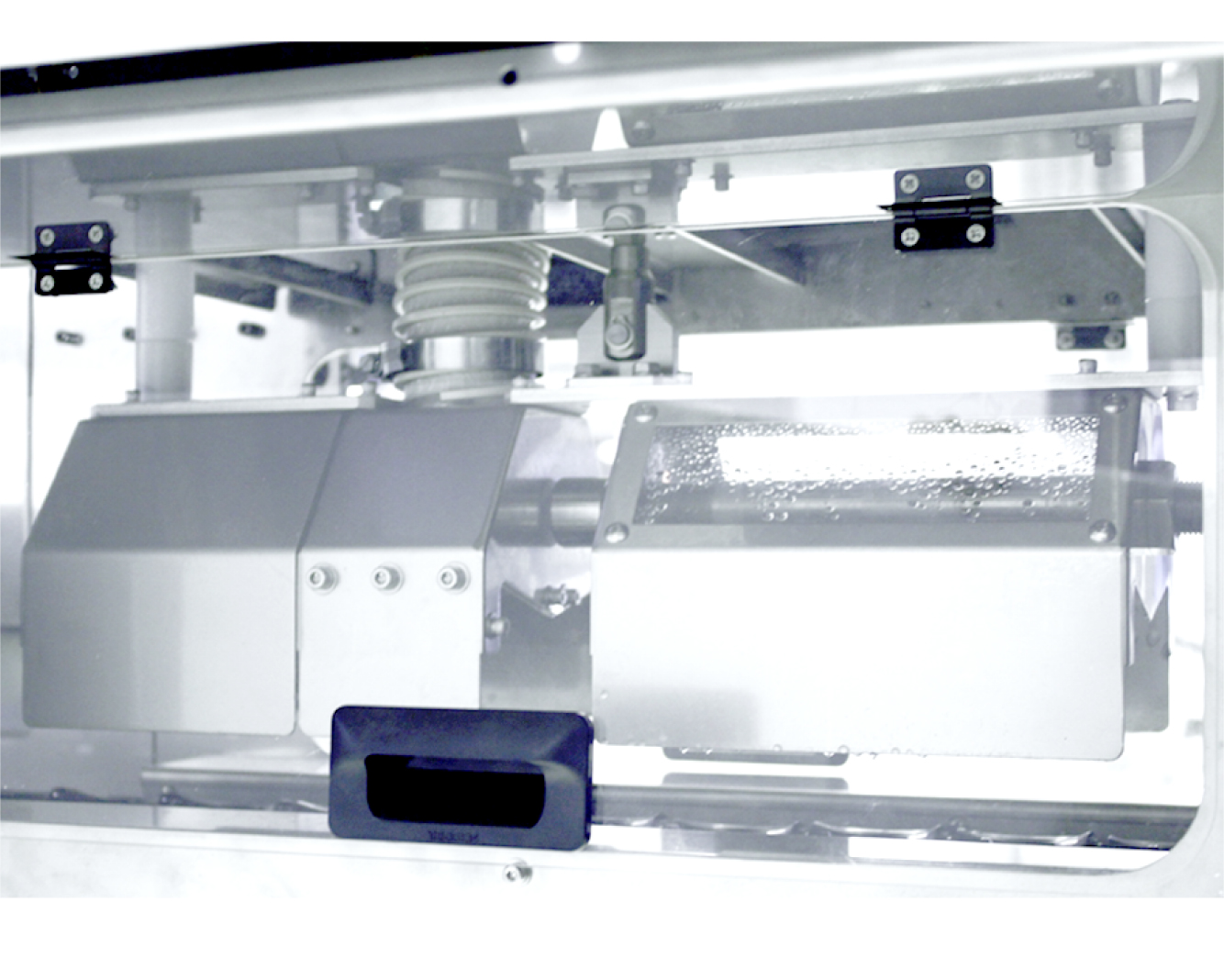

CIP system

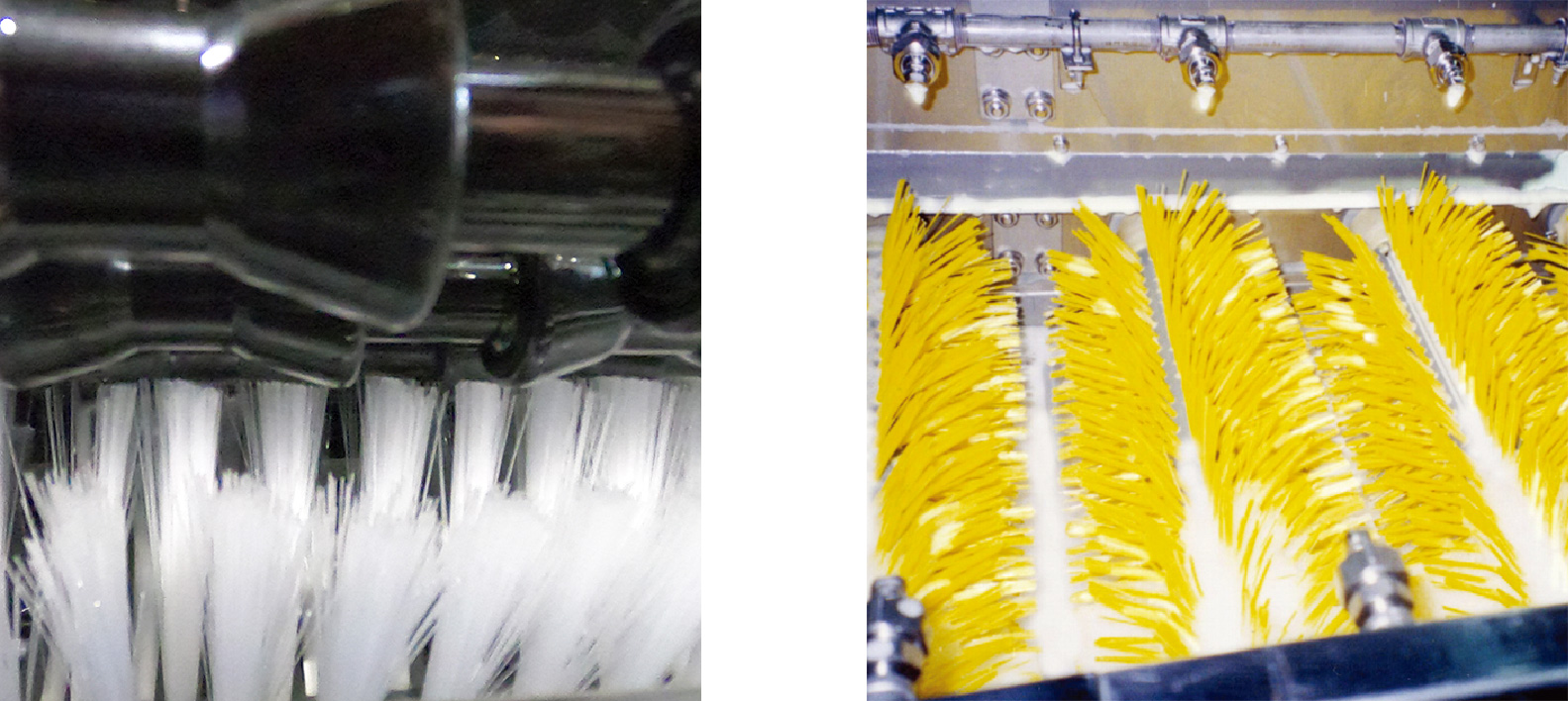

Carrier Washer

CIP (Cleaning in Place) has been introduced in each part to facilitate maintenance and extend the machine life. The carrier, roller, and bucket are automatically cleaned without disassembling.

Carrier Bucket

Roller Washer Brush

Detectors

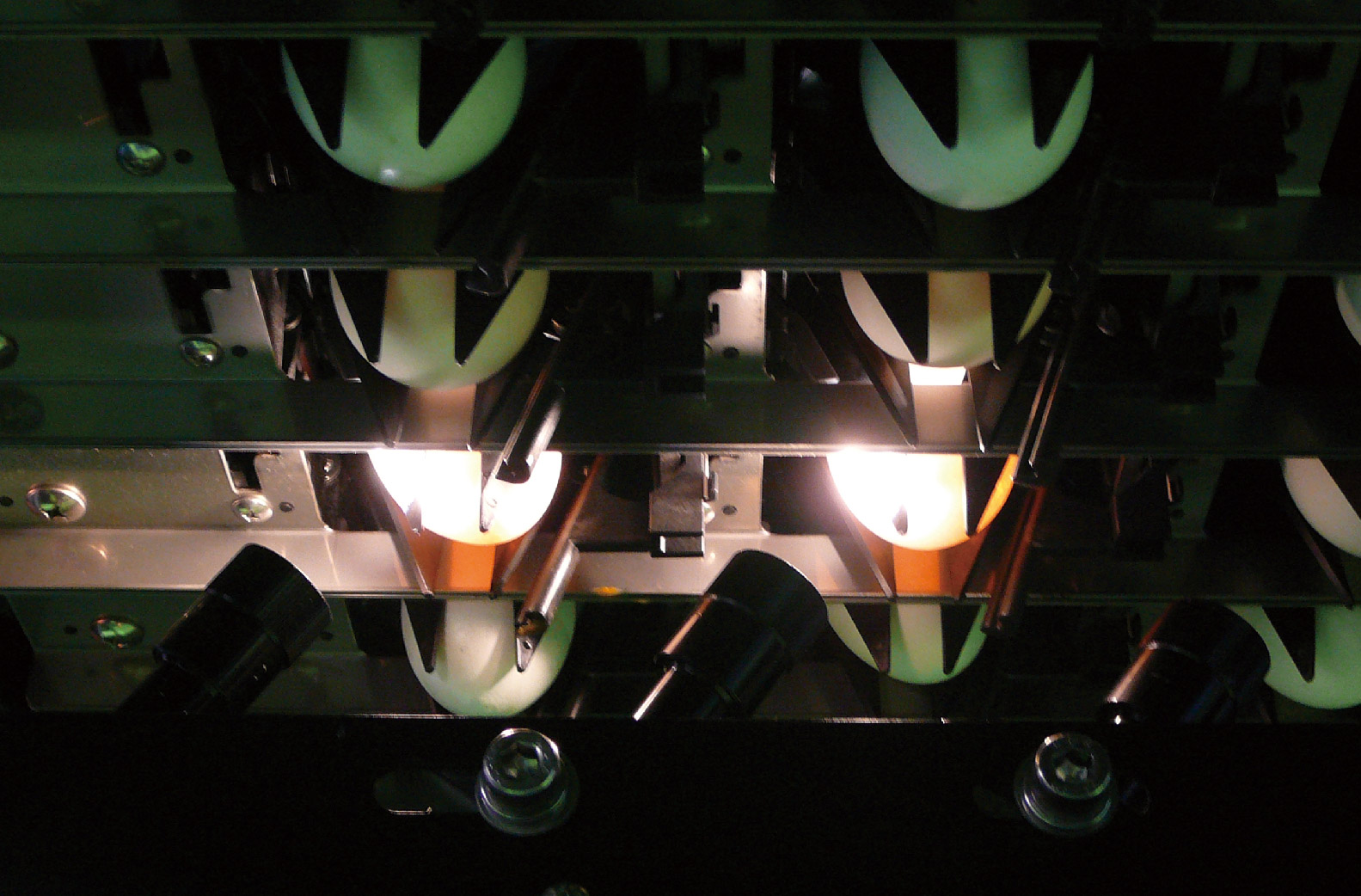

Automatic Crack Detector

Automatic Dirt Detector

Abnormal Egg Detector

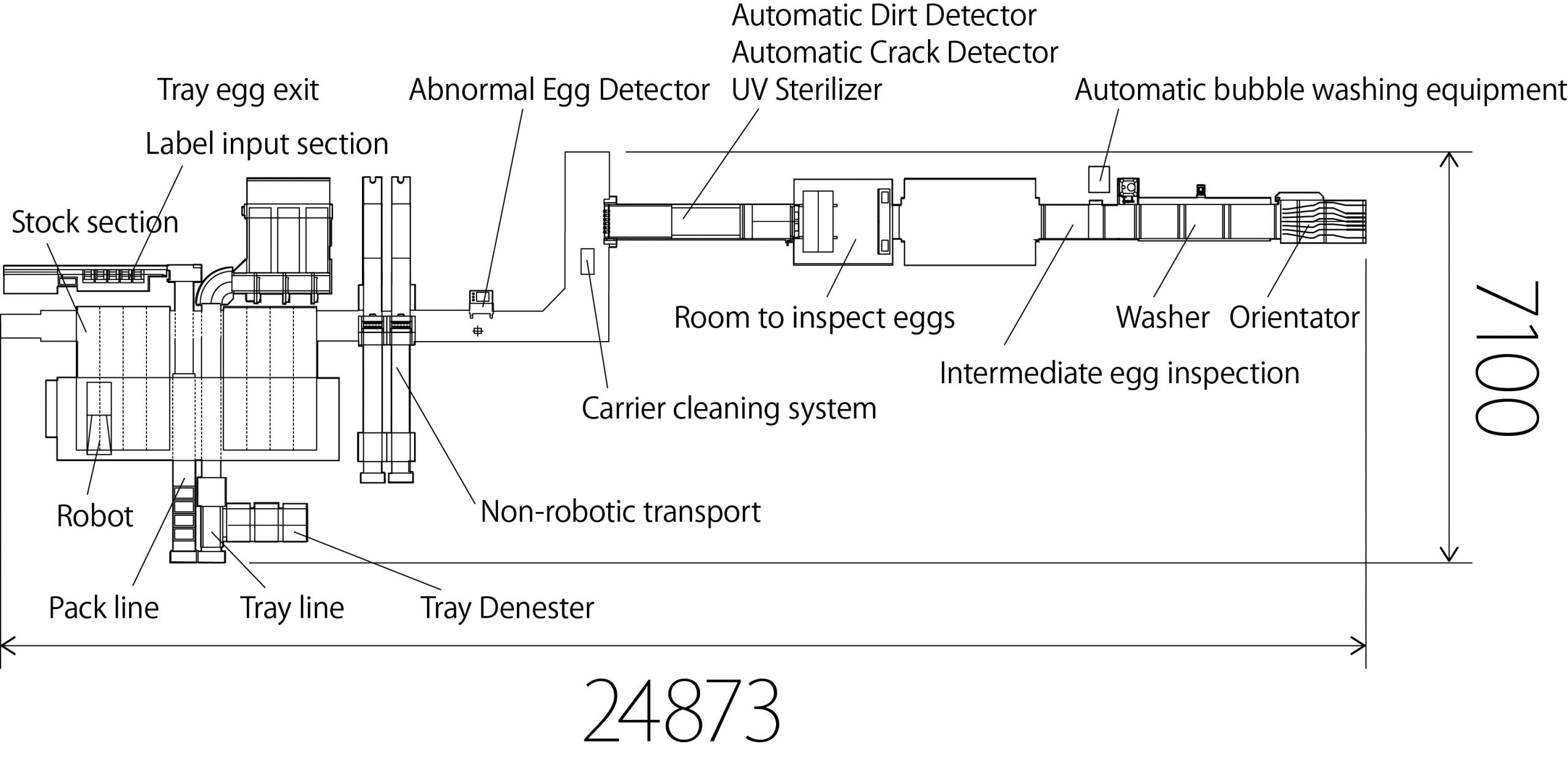

Layout

*This layout is an example.

Specifications

| Code | C-NAEGS4000 | C-NAEGS3500 |

|---|---|---|

| Capacity (Max.) | 40,000 eggs/hr. | 35,000 eggs/hr. |

| Power | 3-phase 200V *1 1-phase 100V *1 |

|

| Air consumption | 50 – 100 L/min. (ANR) ※2 | |

| Water ※3 | more than 60℃ 10L/min. | |

| Available packs / trays | Plastic pack (12P, 10P, 8P, 6P) ※4 Pulp mold carton (12P, 10P) ※5 Standard 30-eggs tray 30-eggs pulp mold tray |

|

| Working environment |

Temperature : 0 – 40℃ Humidity : 45 – 80% ※6 |

|

*1 Varies according to machine specifications.

*2 This may vary depending on specifications.

The above values do not include any amount consumed in the feeding and candling parts.

*3 Water supply facilities are not included.

*4 12P, 8P and 6P are optional

*5 Pulp mold carton support is optional.

*6 No condensation

Designs and specifications are subject to change without notice.

*2 This may vary depending on specifications.

The above values do not include any amount consumed in the feeding and candling parts.

*3 Water supply facilities are not included.

*4 12P, 8P and 6P are optional

*5 Pulp mold carton support is optional.

*6 No condensation

Designs and specifications are subject to change without notice.