Products

Automatic Crack Detector

Detector

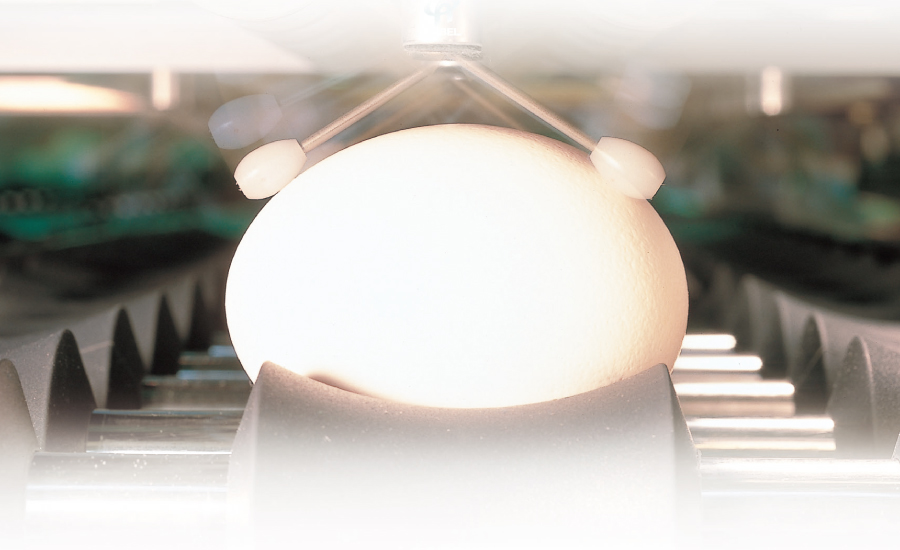

Cracked eggs detected by echo

When eggs are gently tapped with tappers, the acoustic feedback is converted into quantitative data using Fourier transformation. It boasts a 95% detection rate and can detect even invisible cracks.

Video

Features

Rapid detection

16 tappers gently tap the eggs entire surface, generating enormous amounts of data to detect cracks by an instant.

Built-in egg size sensors

Egg size sensors are built in to increase the accuracy on small eggs, which was difficult for previous models.

Easy maintenance

The heavy main body part can be opened and closed easily by simply turning the handle.

Easy to clean and maintain, even in small spaces.

Easy to clean and maintain, even in small spaces.

Adjustable monitor position

The monitor can be adjusted for ease of visibility and access. We have resolved issues such as visibility difficulties with the screen due to reflection and the monitor being positioned too high.

Specifications

| Code | ACD180 | ACD097 | ACD067 | ACD038 |

|---|---|---|---|---|

| Conveying rows | 18 rows | 12 rows | 6 rows | |

| Capacity (Max.) | 180,000 eggs/hr. |

120,000 eggs/hr. |

80,000 eggs/hr. |

40,000 eggs/hr. |

| Power | 1-phase 200V 3.8A |

1-phase 200V 2.7A |

||

| Working environment |

Temperature : 0 – 40°C Humidity : 45 – 80% *1 |

|||

*1 No condensation

Designs and specifications are subject to change without notice.

Designs and specifications are subject to change without notice.