Products

Automatic Leak Detector

Detector

Detection of badly-damaged eggs using image analysis

The Detector detects leaking eggs using high-precision cameras and image analysis. It leads to more stable detection results, compared to the detection by human eyes.

Video

Features

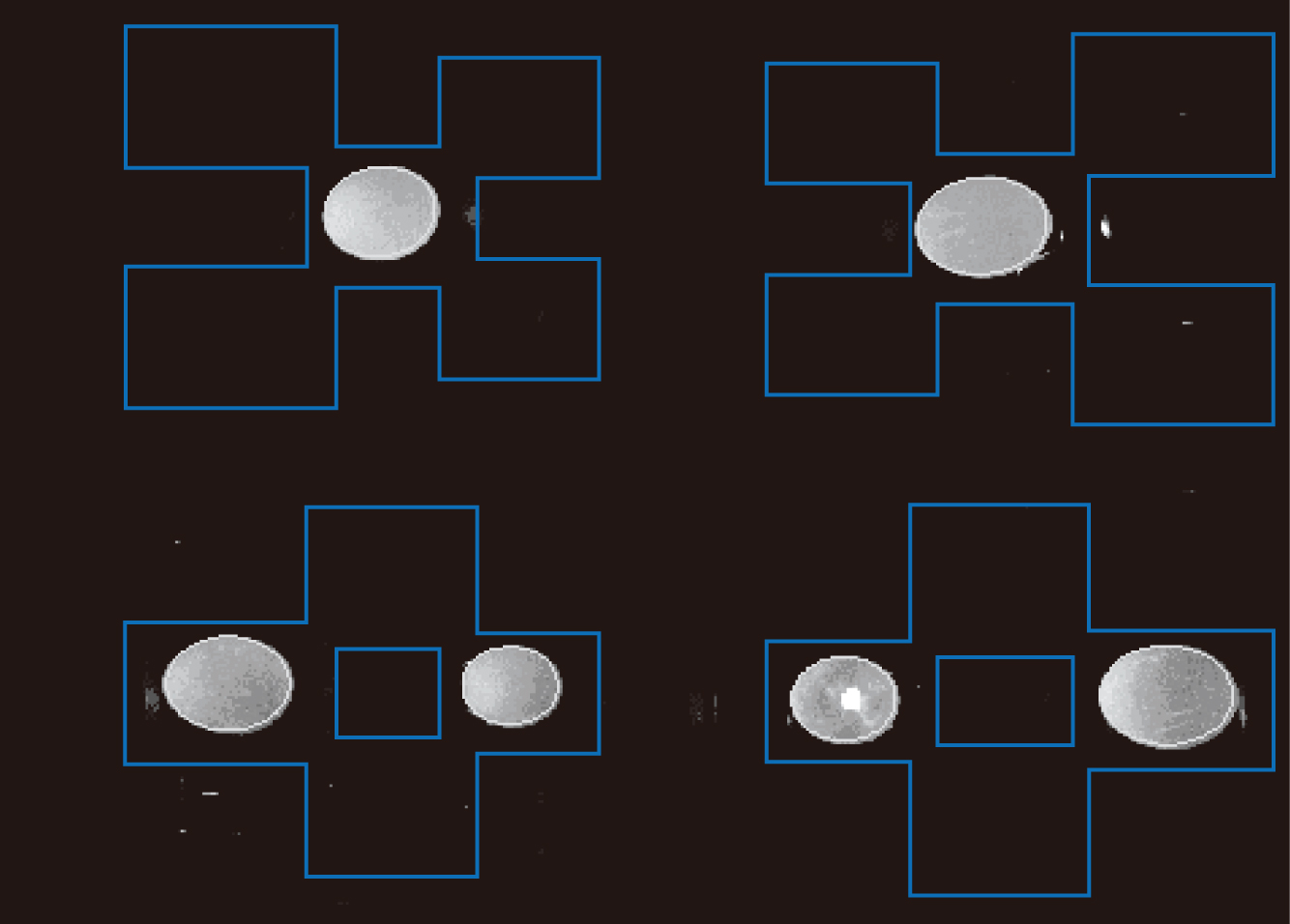

Detection samples

The Detector flags as leaking eggs any eggs whose shells have cracks or holes, broken eggs with intact shell membranes or liquid leakage, and removes them from the line.

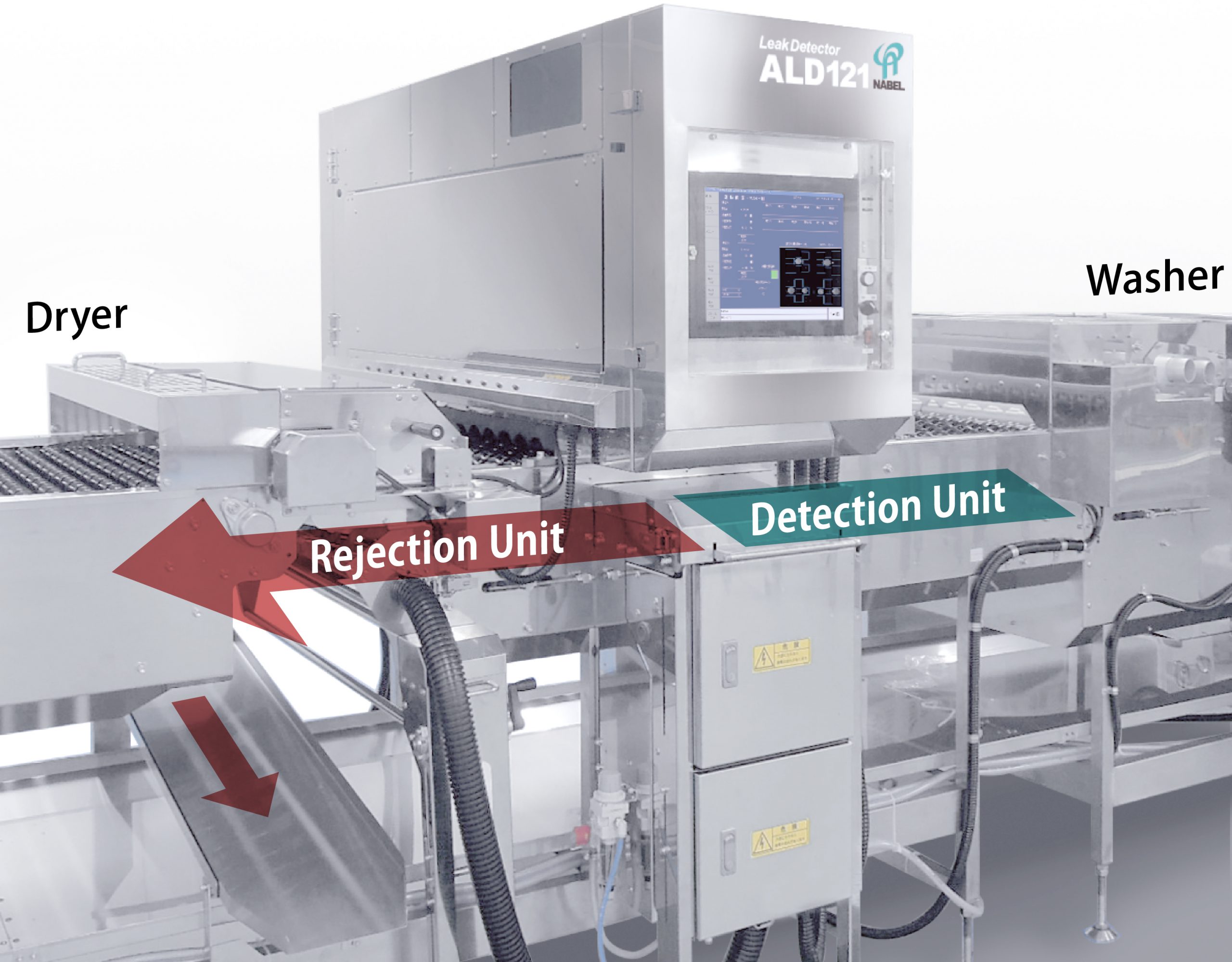

Elimination of badly-damaged eggs via interim egg inspection

The detector eliminates badly-damaged eggs between phases in the washer and dryer (interim egg inspection) to prevent surrounding eggs and other items from being contaminated.

Precise inspection by image analysis

Even wet eggs just after washed are inspected and leaking eggs are removed, before they get into clean zone.

Specifications

| Code | ALD180 | ALD121 | ALD612 | ALD607 |

|---|---|---|---|---|

| Conveyor rows | 18 rows | 12 rows | 6 rows | |

| Capacity (Max.) | 180,000 eggs/hr. |

120,000 eggs/hr. |

80,000 eggs/hr. |

40,000 eggs/hr. |

| Power (Max.) | 1-phase 200V 10.5A | 1-phase 200V 7.8A |

1-phase 200V 5.1A |

|

| Air consumption *1 | 370L/min. (ANR) | 250L/min. (ANR) | 170L/min. (ANR) | 90L/min. (ANR) |

| Working environment |

Temperature : 0 – 35℃ Humidity : 45 – 80% *2 |

|||

*1 Including Rejection Unit

*2 No condensation

Designs and specifications are subject to change without notice.

*2 No condensation

Designs and specifications are subject to change without notice.