Products

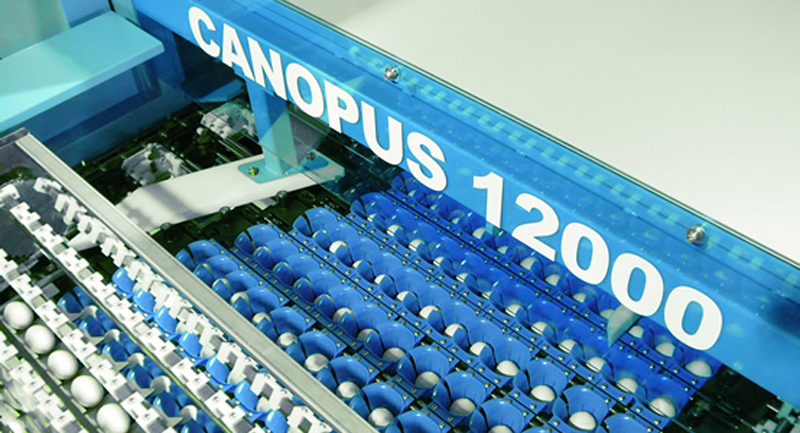

CANOPUS Series

Grading

Slow and gentle high-capacity machine

Video

Features

Narrow Pitch Carrier

Narrow Pitch Carrier moves slowly and process larger capacity. Since the carrier pitch is narrow, the carrier speed is suppressed, and the impact on the egg can be minimized.

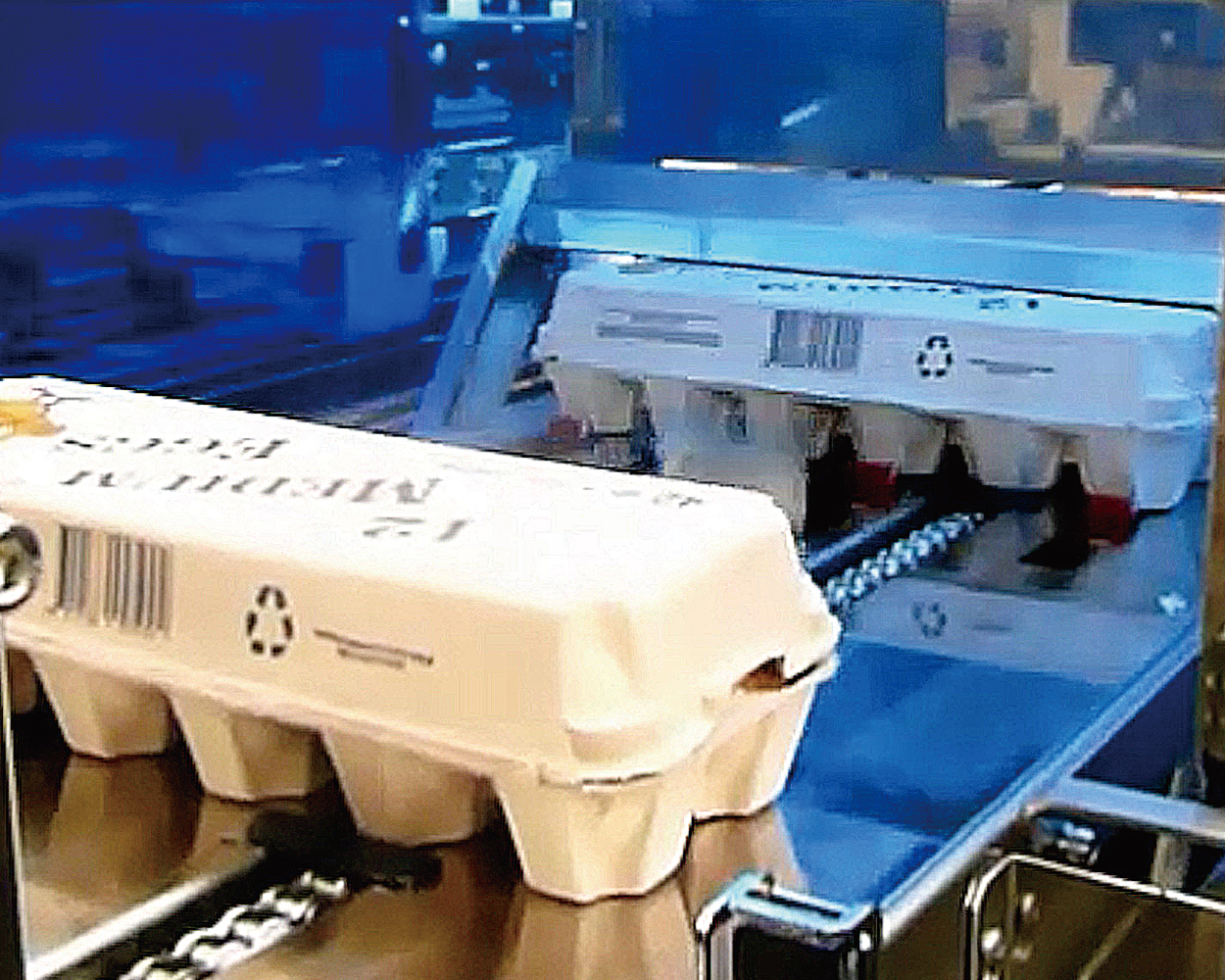

Direct packing

Packing eggs sorted by size directly from intermediate buckets into containers allows for efficient sorting with large quantities of eggs.

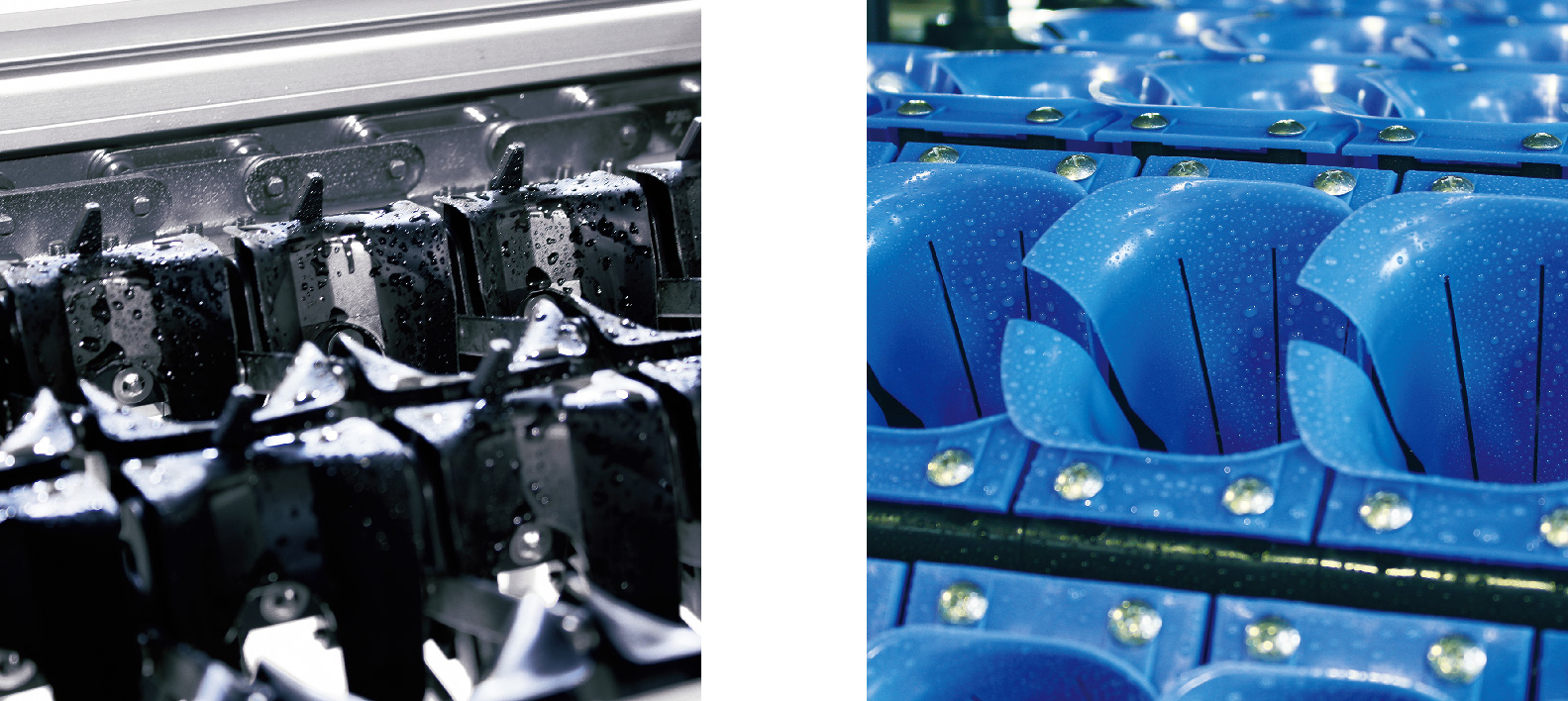

Made of stainless steel

The frame is made of stainless steel, which is resistant to rust and stains, making it durable and easy to clean.

Options

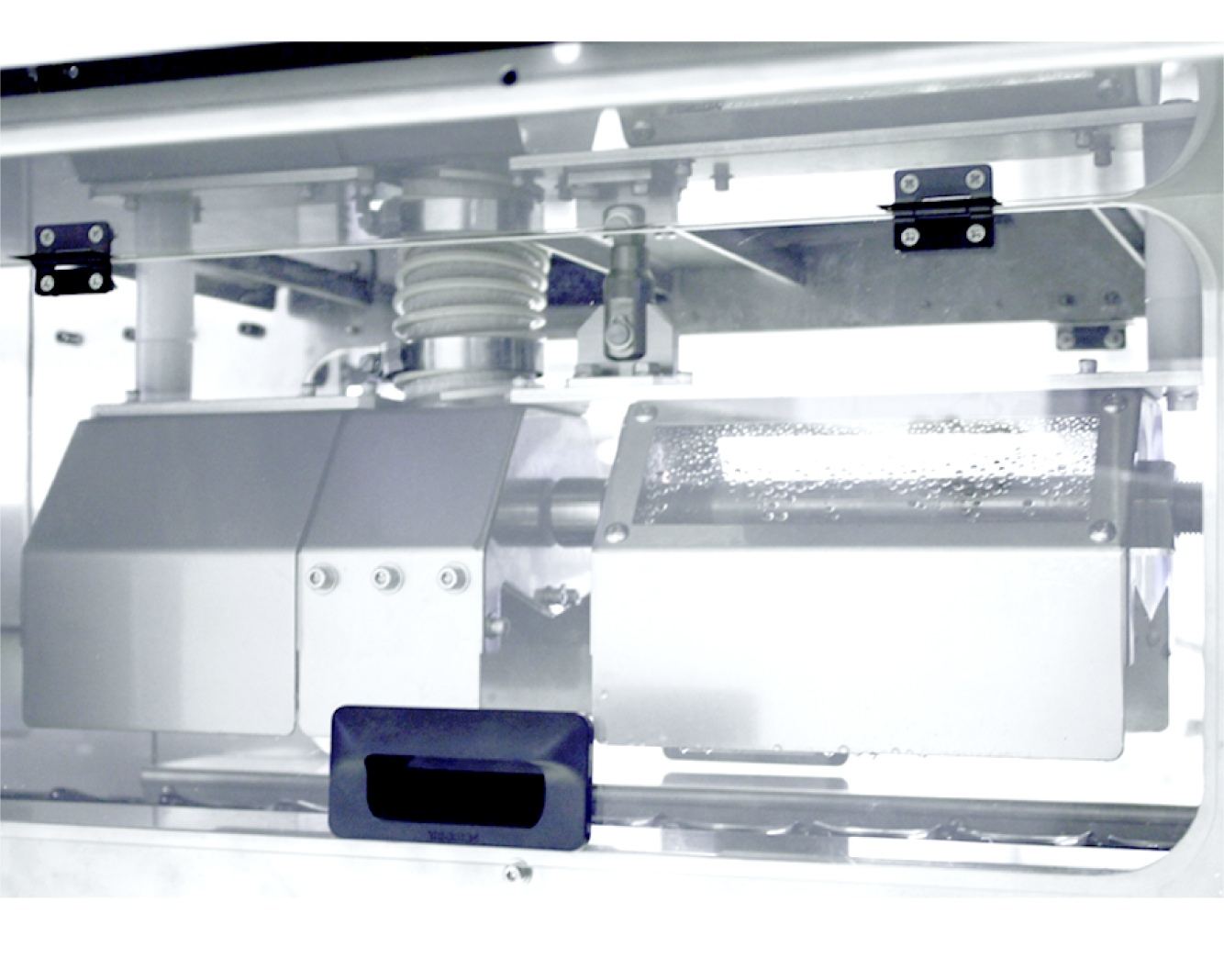

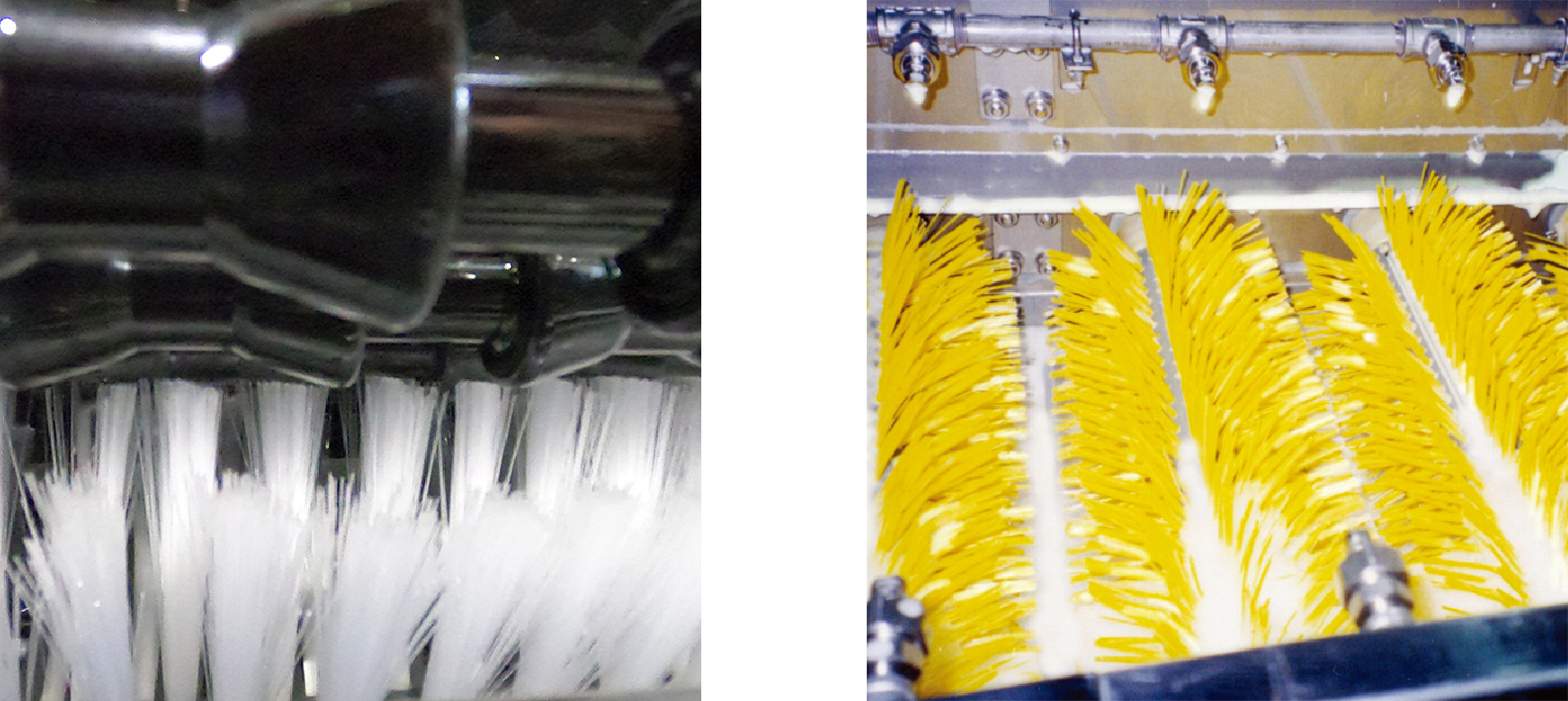

Washer & Dryer

The Washer & Dryer automatically washes and dries eggs oriented by accumulators. Instead of pouring egg wash water over the eggs, it brushes them while rolling them in the hot water to remove any dirt.

Washing process

Eggs soaked in water are washed with rotating egg-washing brushes. After washing, a mixture of hot water and sodium hypochlorite is applied to clean and sterilize the eggshell surface.

Eggs soaked in water are washed with rotating egg-washing brushes. After washing, a mixture of hot water and sodium hypochlorite is applied to clean and sterilize the eggshell surface.

Drying process

Water is blown out of the surface of eggs by the air shot at the exit of the washer. After that, the eggs are dried up by drying brushes and by air from pressurized fans over the eggs.

Water is blown out of the surface of eggs by the air shot at the exit of the washer. After that, the eggs are dried up by drying brushes and by air from pressurized fans over the eggs.

Carton Closer

The Carton Closer identifies the pulp mold carton filled with eggs and closes the lid. It does not close the lid of the carton if any of the eggs are missing.

Supports packs of various sizes

It can close the lid of 10, 12, 15, and 18 pulp mold cartons and plastic button packs.

It can close the lid of 10, 12, 15, and 18 pulp mold cartons and plastic button packs.

CIP system

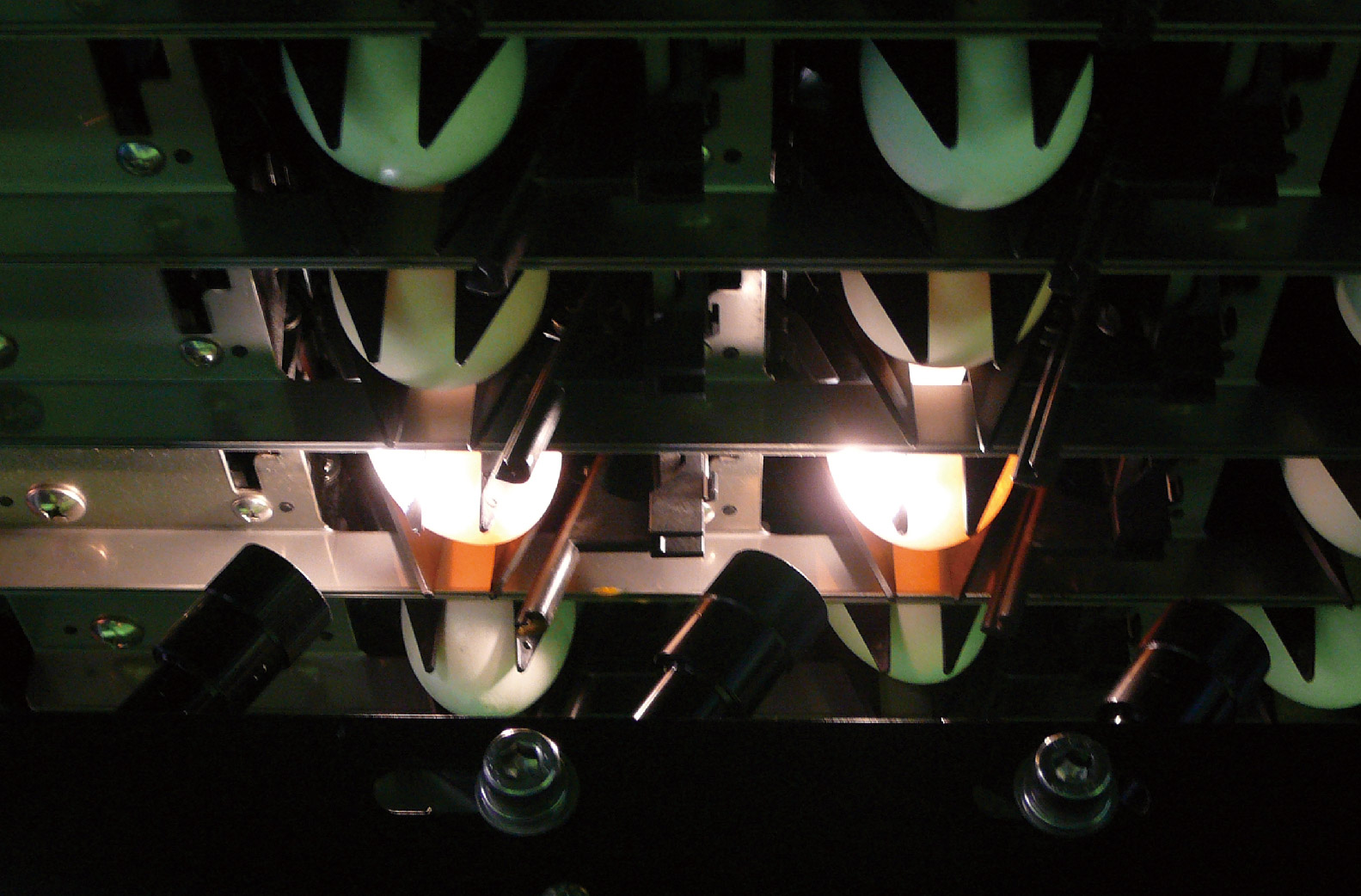

Carrier Washer

CIP (Cleaning in Place) has been introduced in each part to facilitate maintenance and extend the machine life. The carrier, roller, and bucket are automatically cleaned without disassembling.

Carrier Bucket

Roller Washer Brush

Detectors

Automatic Crack Detector

Automatic Dirt Detector

Automatic Dirt Detector

Automatic Leak Detector

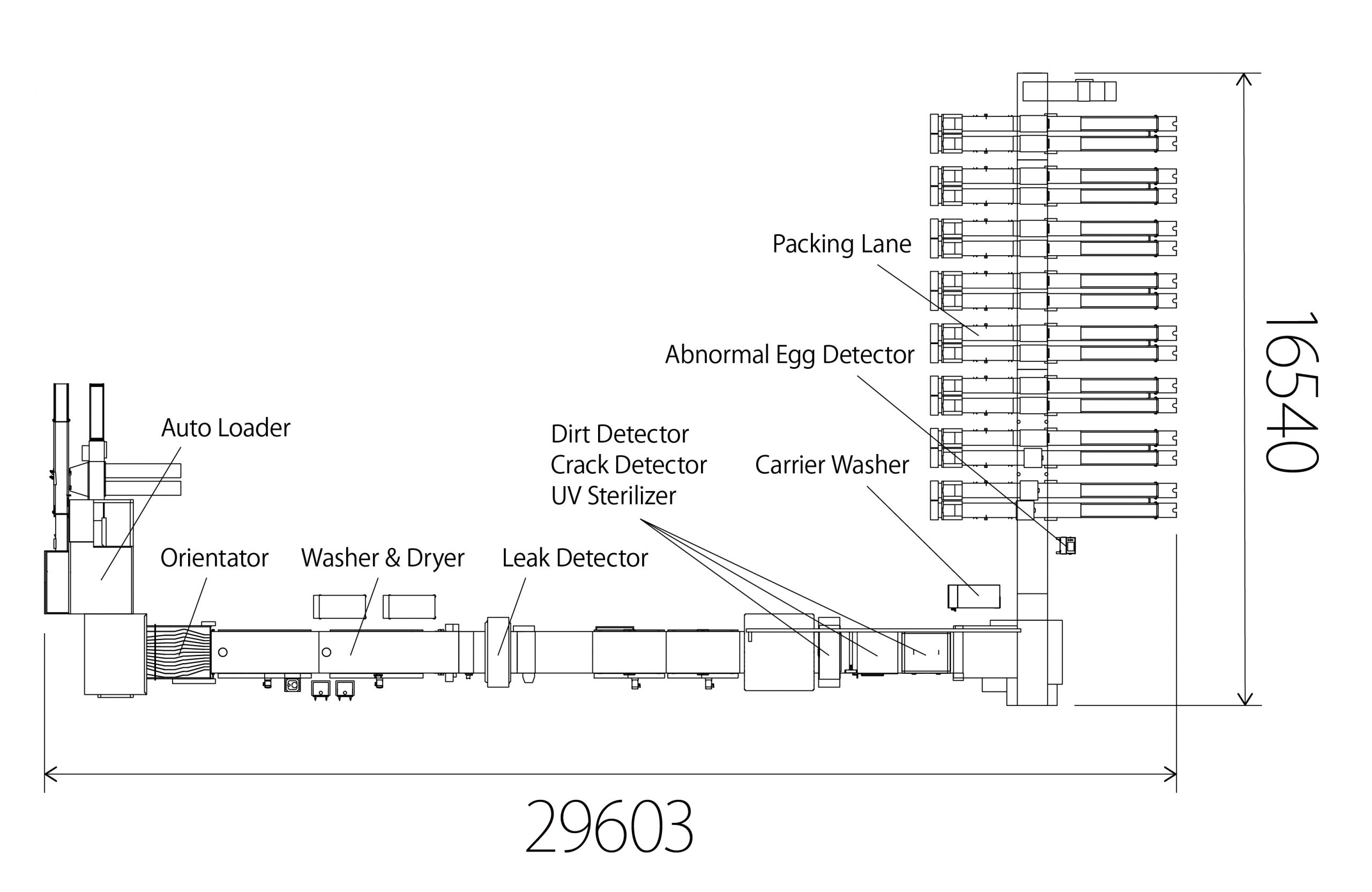

Layout

*This layout is an example.

Specifications

| Code | CANOPUS24000 | CANOPUS18000 | CANOPUS12000 | CANOPUS8000 | CANOPUS4000 |

|---|---|---|---|---|---|

| Track | 6 tracks | 5 tracks | 3 tracks | 2 tracks | 1 track |

| Capacity (Max.) | 240,000 eggs/hr. | 180,000 eggs/hr. | 120,000 eggs/hr. | 80,000 eggs/hr. | 40,000 eggs/hr. |

| Power | 3-phase 200V *1 | ||||

| Working environment |

Temperature : 0 – 40℃ Humidity : 45 – 80% *2 |

||||

*1 Varies according to machine specifications.

*2 No condensation

Designs and specifications are subject to change without notice.

*2 No condensation

Designs and specifications are subject to change without notice.