Products

Embryonated Egg Inspector

Hatching eggs

Inspection of eggs for vaccine production using AI technology

The machine uses AI to inspect images of developing eggs taken by irradiating LED light on them, determining whether they are suitable for vaccine production. It can inspect eggs that have passed 10 and 11 days after the start of incubation and remove defective eggs in the rejection section.

Features

Detection samples

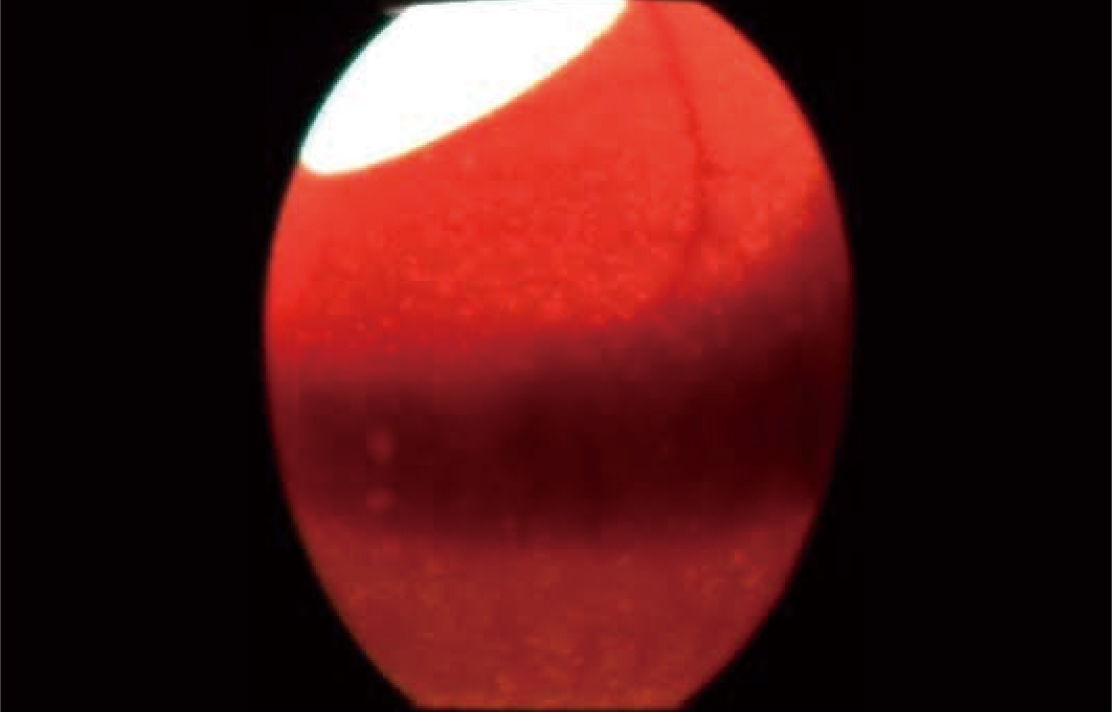

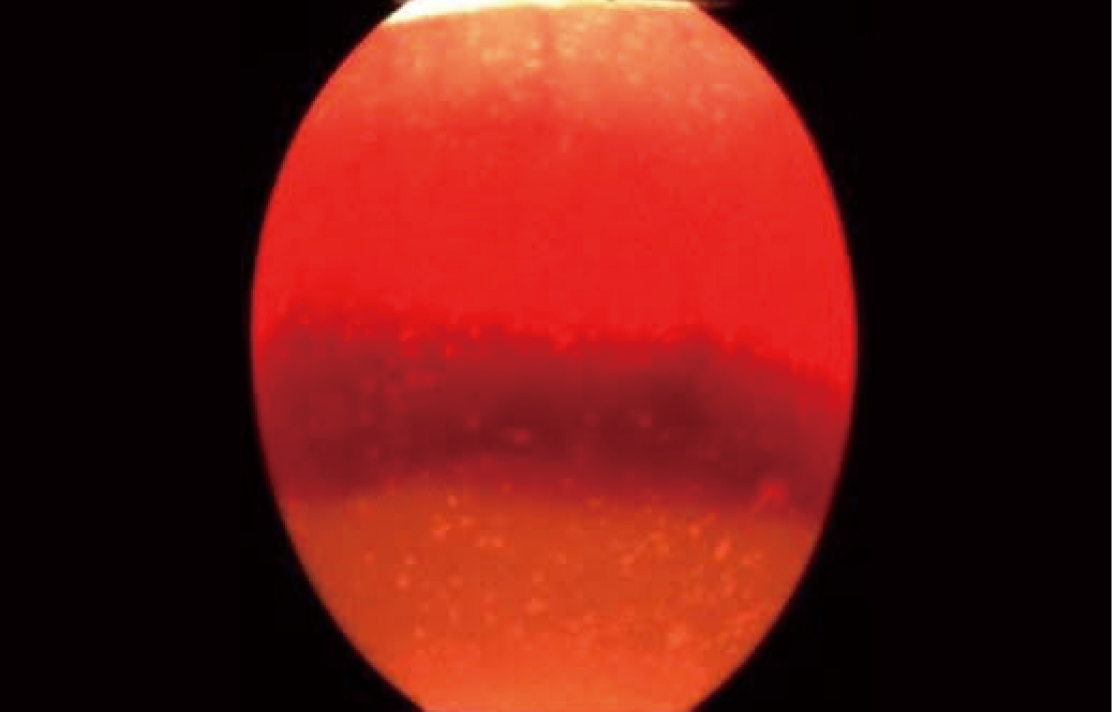

The machine inspects the condition of developing eggs, with conditions including good eggs, unfertilized eggs, dead eggs, inverted eggs, large air cells, slanted air cells, side air cells, and stunted eggs.

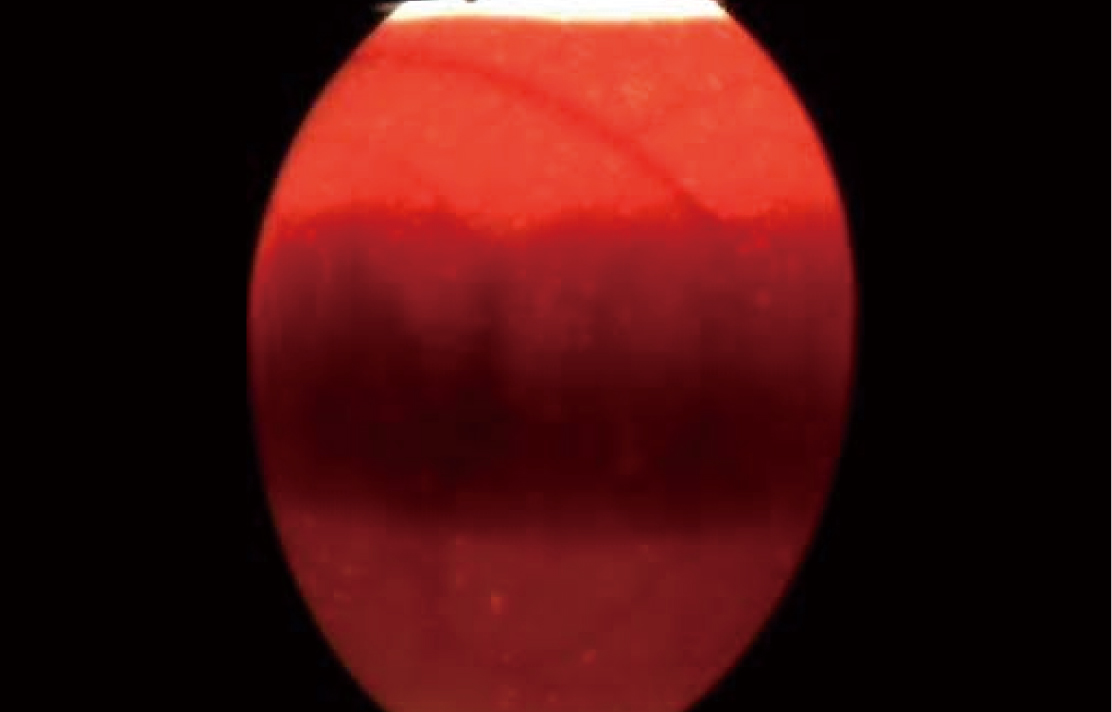

Good egg

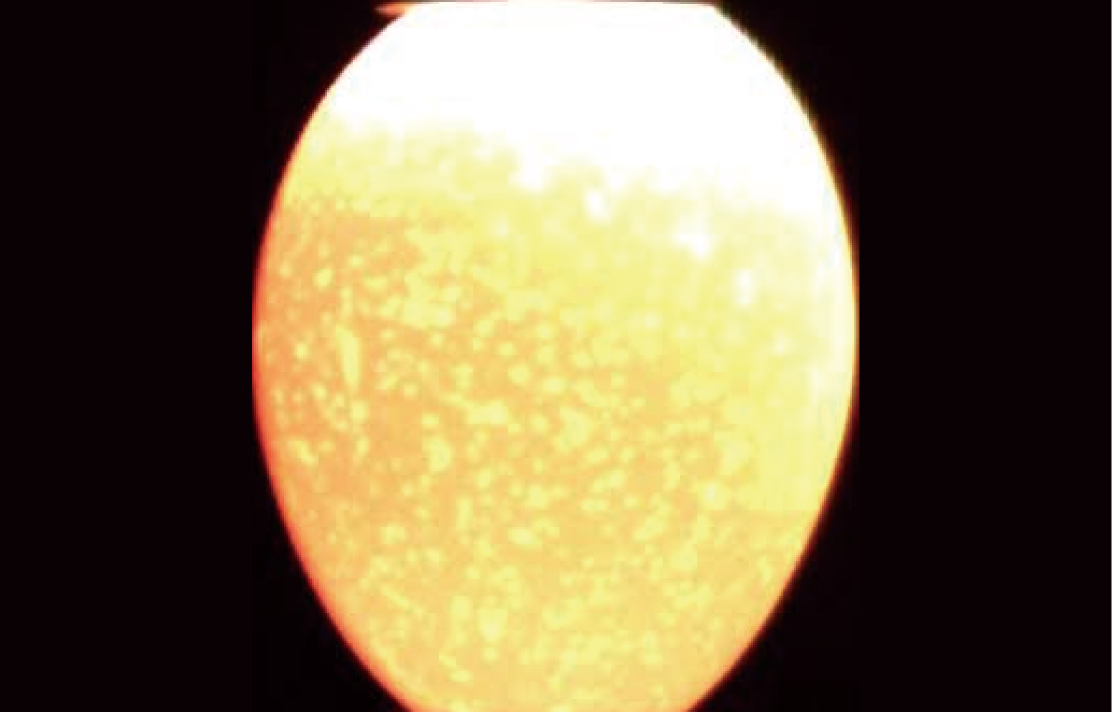

Unfertilized egg

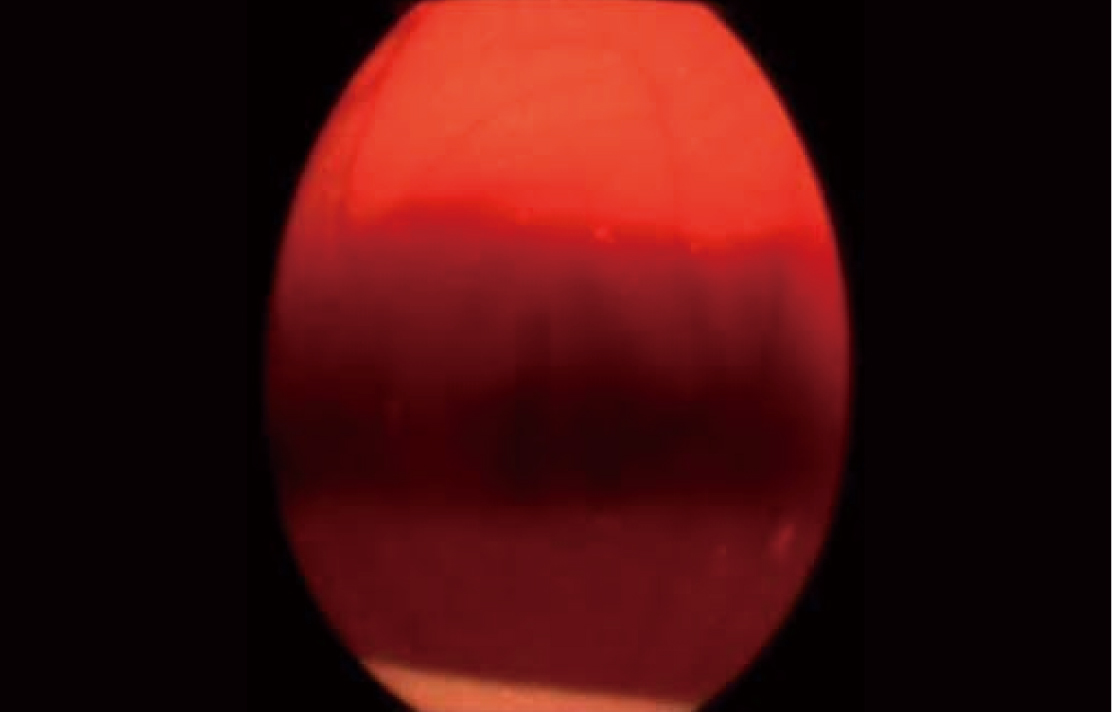

Dead egg

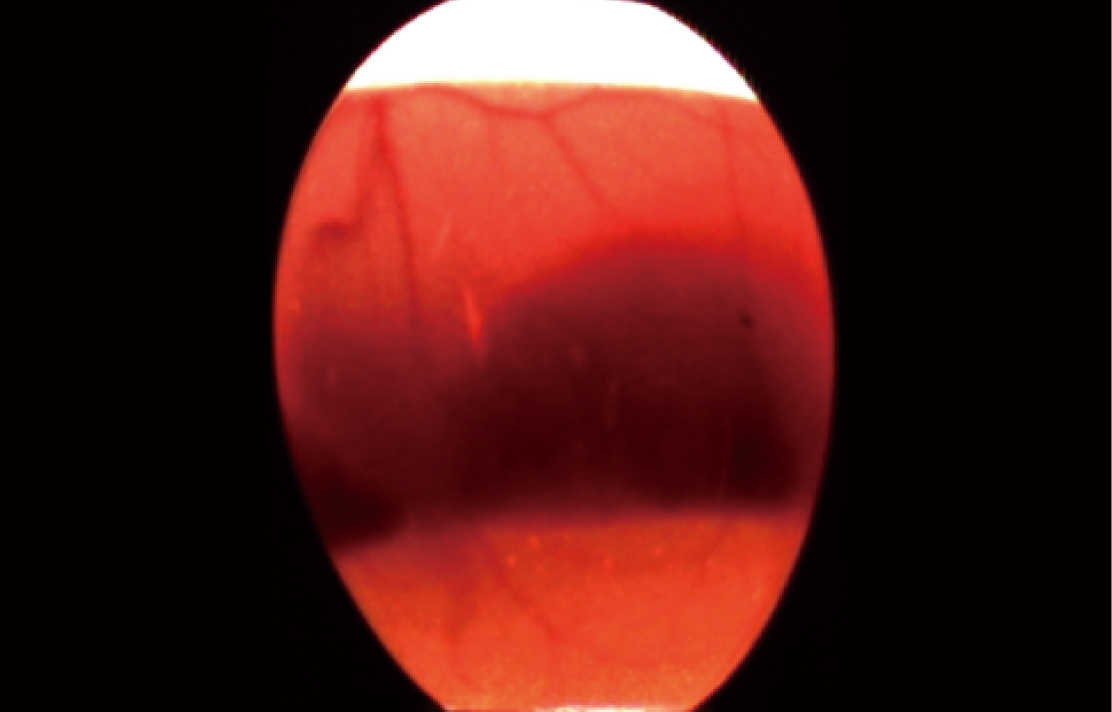

Inverted

Large air cell

Slanted air cell

Side air cell

Stunted

Inspection status displayed in real time

The machine displays the number of eggs passing, the number of good eggs, the number of eggs eliminated, and a breakdown of defective eggs in real time. In addition, as independent determination levels can be set for each inspection item, certain items can be selected for strict inspection.

Handling technology to minimize physical impact

Based on our delicate handling technology developed for edible egg products, the machine carefully inspects eggs one by one while minimizing physical impact. This results in both of highly accurate inspections and the maintenance of egg quality.

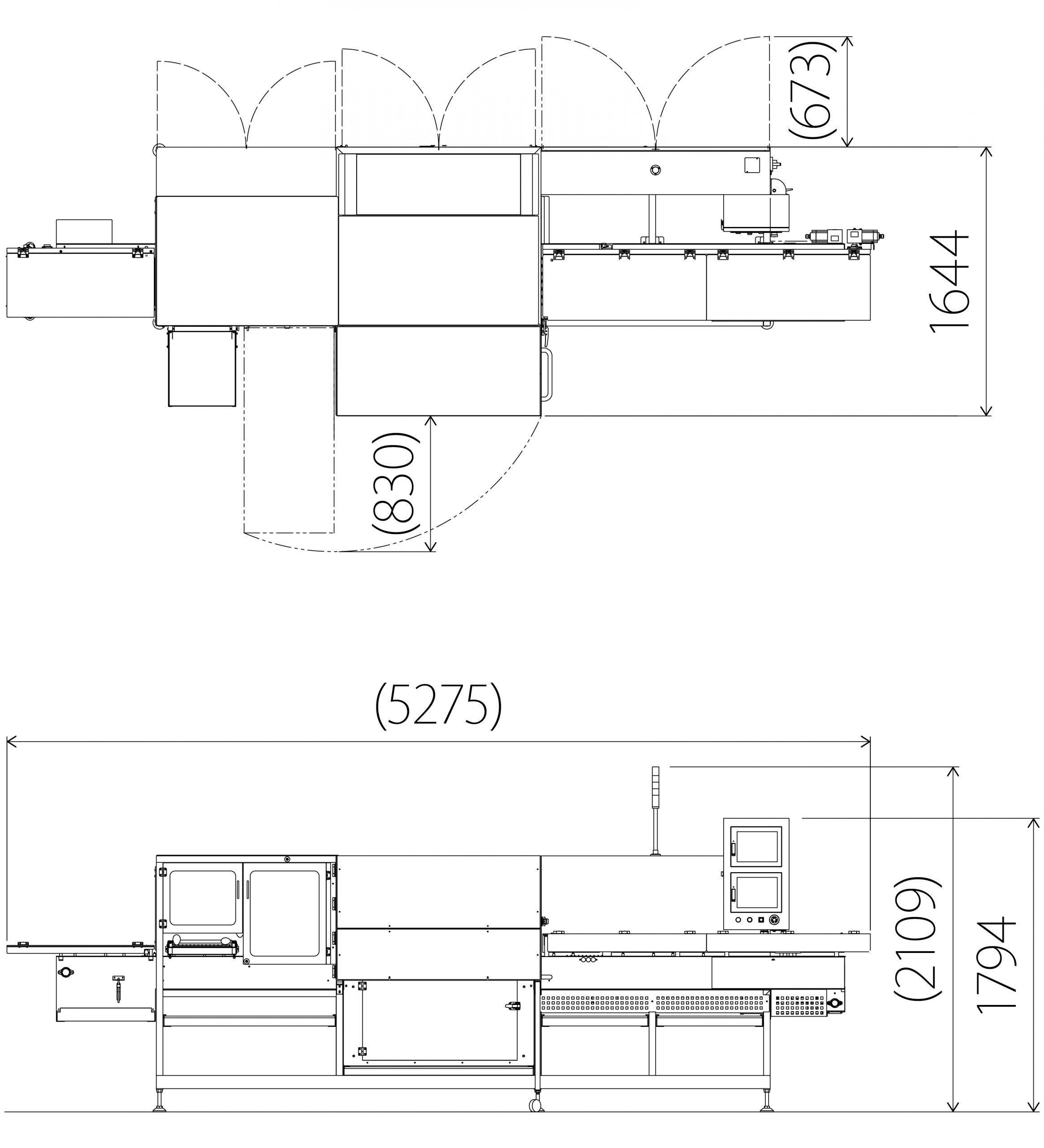

Layout

Specifications

| Code | EEI001 |

|---|---|

| Capacity (Max.) | 36,000 eggs/hr. |

| Power | 3-phase 200V 12.2A |

| Air consumption | 250L/min. (ANR) |

| Air supply pressure | 0.5 – 0.7MPa |

| Working environment |

Temperature : 0 – 40°C Humidity : 45 – 80% ※1 |

| Sorting target | Developing chicken eggs |

| Available trays | 36 eggs (straight 6 x 6) Made by I.P.Co.,Ltd. |

*1 No condensation

Designs and specifications are subject to change without notice.

Designs and specifications are subject to change without notice.