Products

Farm Packer

Egg collection system

High-speed processing, gentle handling of eggs

This machine incorporates a filling method that is safe for eggs, featuring an accumulator designed for filling efficiency. Even though it is compact, it can handle 40,000 eggs per hour. Easily soiled parts can be detached and washed with water for easy maintenance.

Video

Features

A filling method gentle on eggs

This machine does not hold individual eggs, but fills them directly from its accumulator into containers. Quality is maintained by minimizing physical impact to the eggs.

In pursuit of efficiency in egg filling

After adjusting the feeding quantity as appropriately for the three conveyors that run at different speeds, the machine minimizes the occurrence of jamming and heaping when moving eggs.

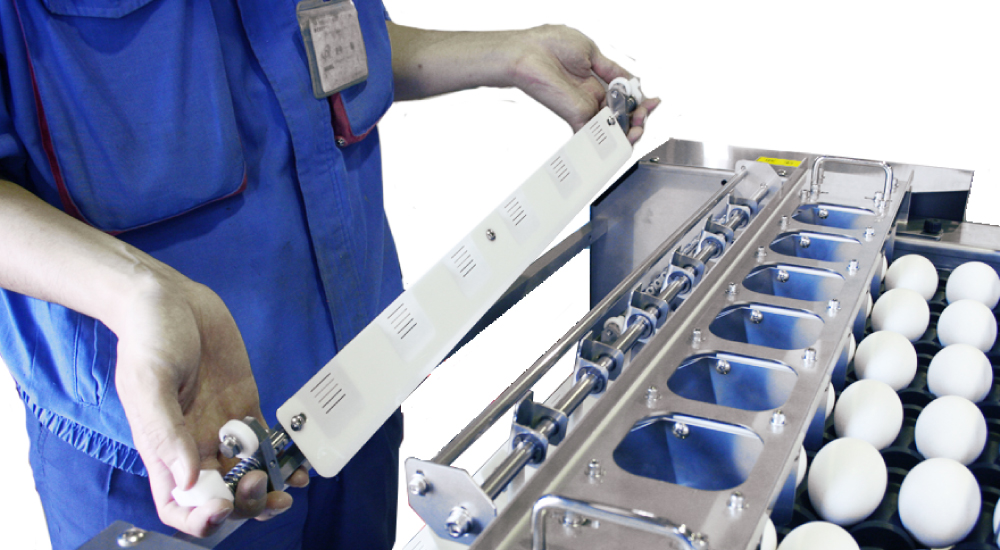

Washable with water for consistent cleanliness

Mechanical parts that can be soiled easily are one-touch detachable for easy washing using water, reducing effort required for maintenance.

Options

Further automation of the egg collection process

Combined with Tray Stacker and tray trolley loader, the egg collection process can be labor-saving.

Tray Stacker ( ATS400 )

The Tray Stacker incorporates a bottom-support design to hold the trays from the bottom, which mitigates the impact on both eggs and trays. It also saves the workers from physically demanding tasks and leads to stable stacking.

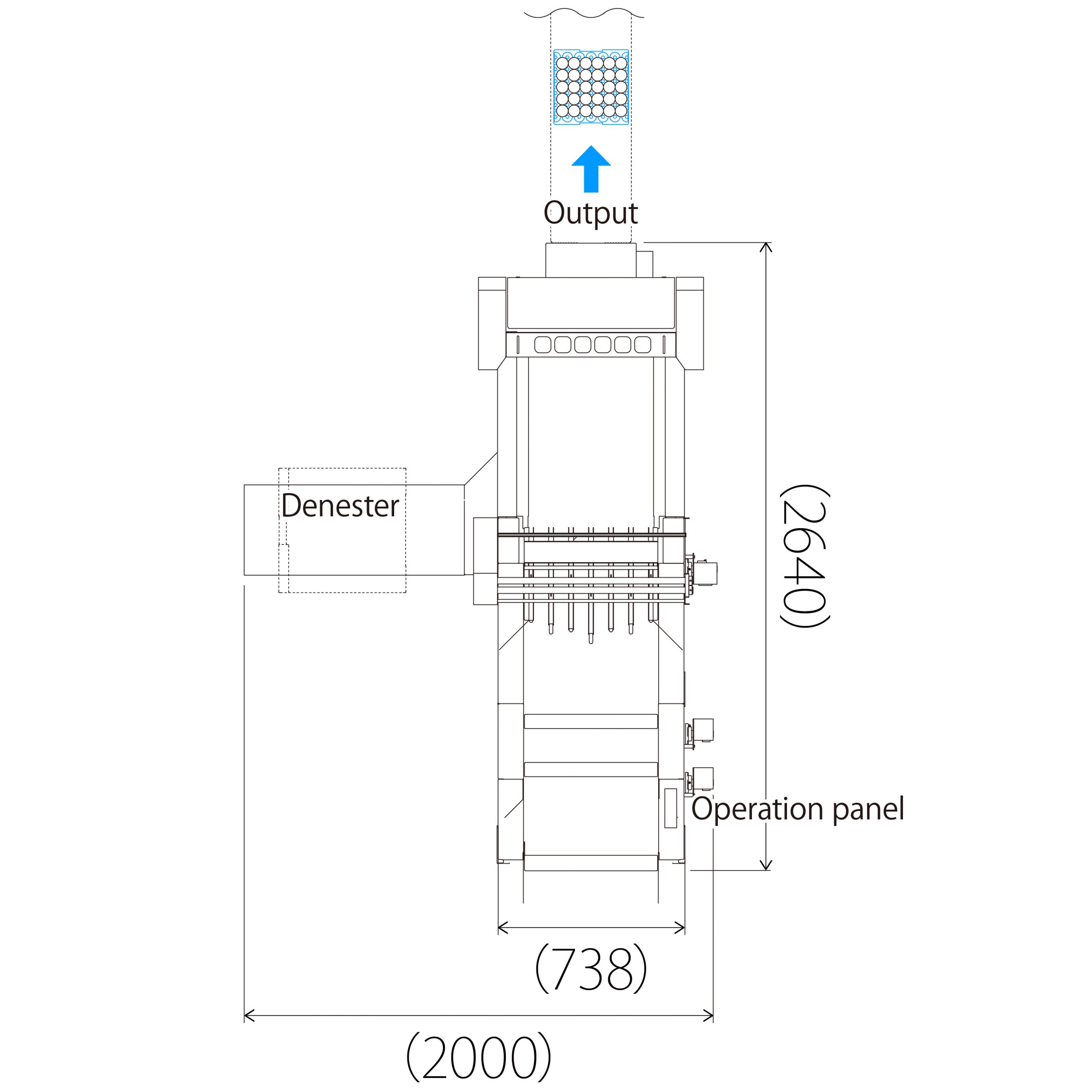

Tray Feeder ( ATF001 )

The Tray Feeder feeds empty trays automatically to the tray denester on the farm packer. It stocks Max. 240 pieces of trays and let operators leave the tray feeding area for the longer period of time, which reduce the required labor.

Layout

Specifications

| Code | FFP4100 |

|---|---|

| Capacity (Max.) | 40,000 eggs/hr. |

| Power | 3-phase 200V 7.5A *1 |

| Working environment |

Temperature : 0 – 40°C Humidity : 45 – 80% *2 |

*1 Includes tray feeder and transfer exit conveyor

*2 No condensation

Designs and specifications are subject to change without notice.

*2 No condensation

Designs and specifications are subject to change without notice.