Products

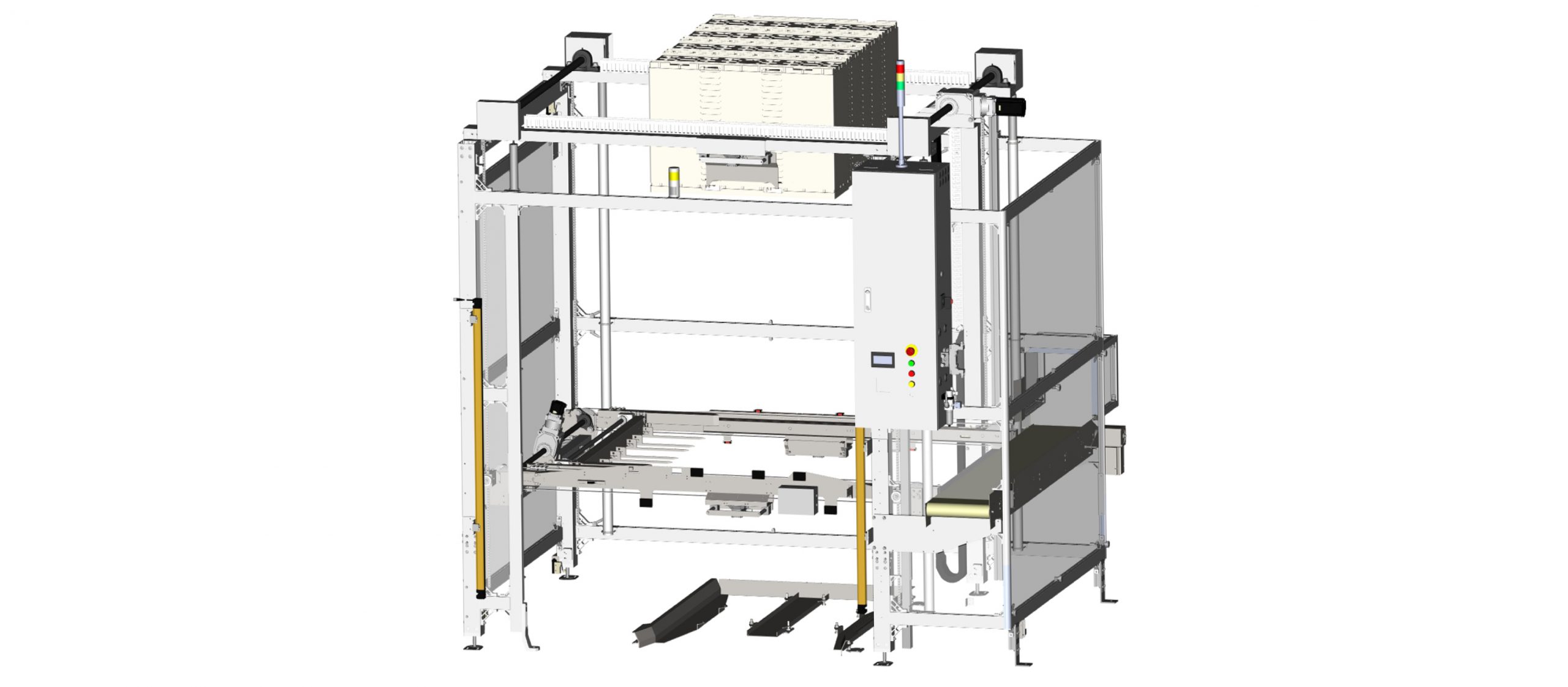

Mini Palletizer / Mini Depalletizer

Egg collection system

Compact and automated palletization

This machine can automate a series of palletizing tasks, from stacking tray stacks to moving dividers. Despite its compact body, it can handle 40,000 eggs per hour.

Features

Compact design

This model has a compact body that fits into a 2.7 m² and requires a much smaller footprint, compared to other robotic palletizers.

Compatible with Pallet Transport System

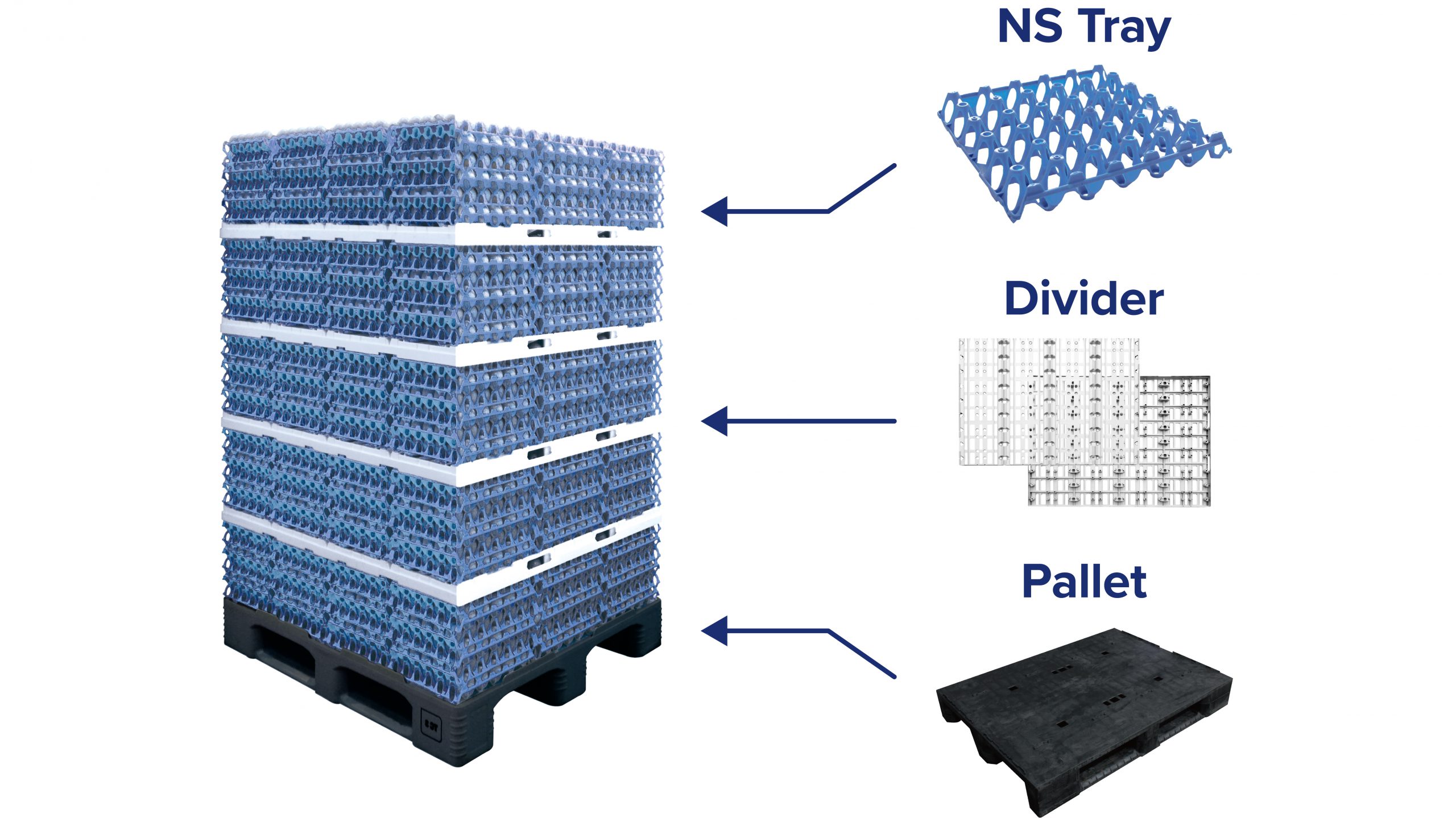

Pallet style is the latest way to transport eggs. The MPL001 can be adapted to EPS system, Egg Cargo System and paper trays.

Smart labor saving, from egg collection to transportation

Using this machine along with the Farm Packer and Tray Stacker allows for automation of egg collection.

Egg tray stacks can be palletized in mass quantities with minimum manpower.

The pallet can accommodate up to 10,800 eggs at once for transportation and can be stacked compactly when returned.

Egg tray stacks can be palletized in mass quantities with minimum manpower.

The pallet can accommodate up to 10,800 eggs at once for transportation and can be stacked compactly when returned.

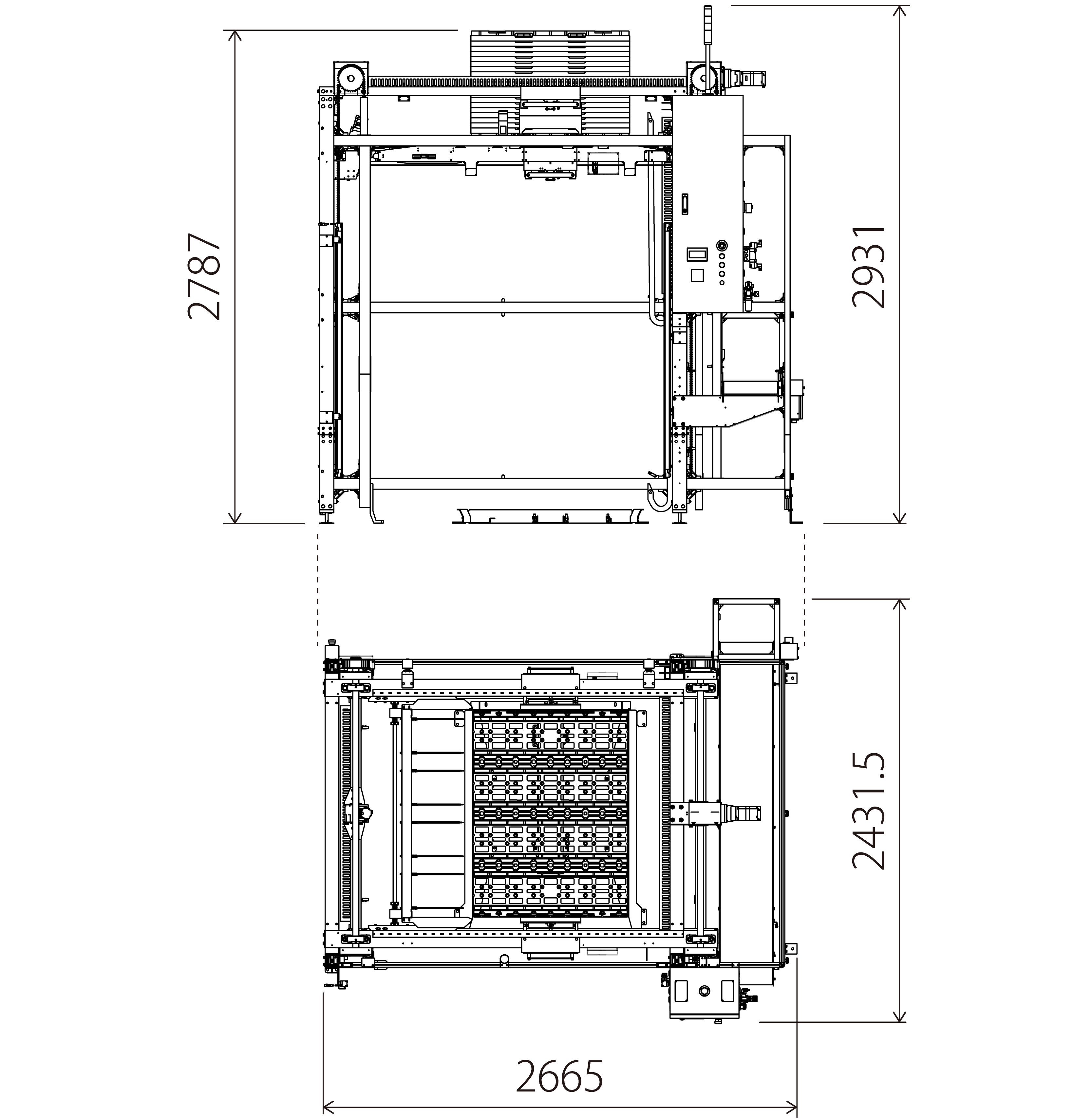

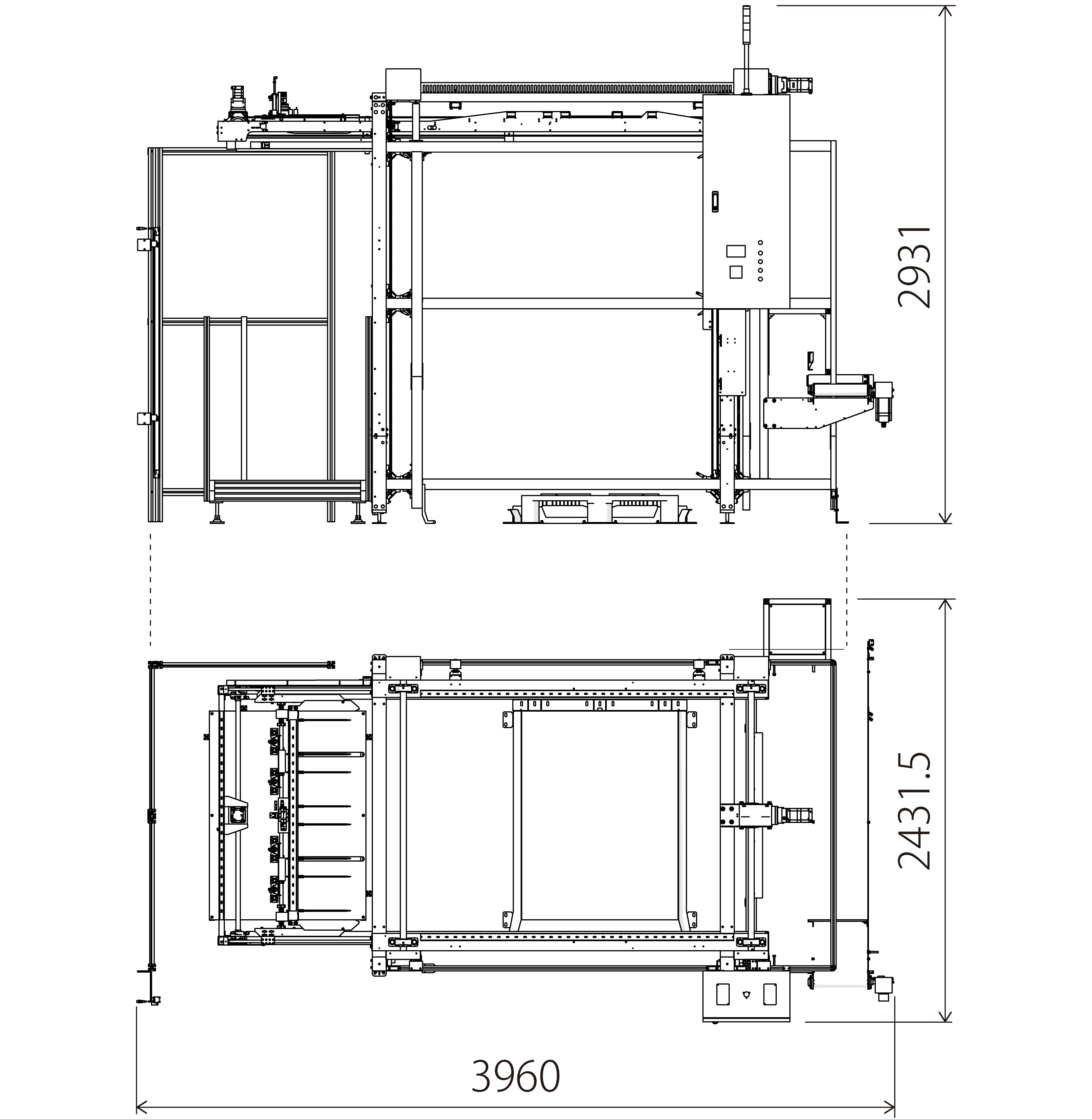

Layout

For EPS system and EggCargoSystem

For 30-eggs pulp mold tray

Specifications

| Code | MPL001/MDL001 |

|---|---|

| Capacity (Max.) *1 | 40,000 eggs/hr. |

| Power *2 | 3-phase 200V 11.8A |

| Air consumption | 2L/min. (ANR) |

| Working environment |

Temperature : 0 – 40℃ Humidity : 45 – 80% *3 |

| Available trays | Egg Production Systems 30-eggs pulp mold tray Eggs Cargo System |

| Number of dividers stocked (Max.) |

20 pcs |

| Numbers of layers on a pallet (Max.) |

5 layers |

*1 However, it depends on the work time for pallet replacement and the amount of tray buffer up to the downstream equipment.

*2 Downstream conveyors are not included.

*3 No condensation

Designs and specifications are subject to change without notice.

*2 Downstream conveyors are not included.

*3 No condensation

Designs and specifications are subject to change without notice.