Products

Pack All Checker

Detector

Comprehensive inspection to improve the quality of packed eggs

This machine detects contamination and cracking at the point and blunt ends of the egg as well as leaks, missing content, and missing eggs. We have achieved a comprehensive system for inspection of packed eggs through the full use of the camera and sensing technology that we have accumulated over the years. This will help ensure uniform quality for packed eggs as well as reduce inspection time and prevent packaging lines from interruption.

Video

Features

Detection samples

This machine detects stains and cracking at the top and bottom ends of eggs in a pack as well as leaks, missing content, missing eggs, etc.

Dirty spot

Crack

Leak

Empty shell

Missing egg

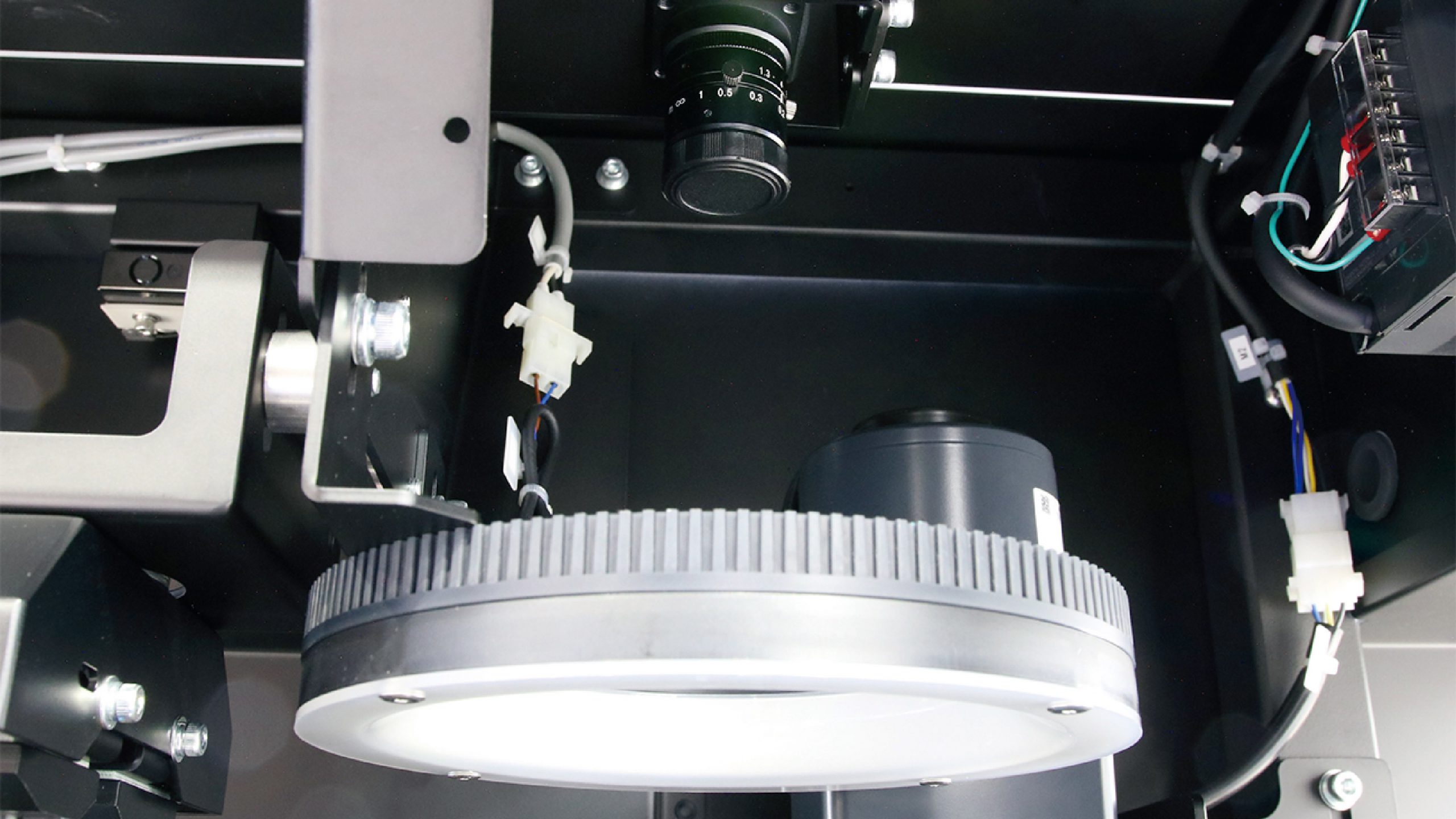

High inspection accuracy

This machine is equipped with a high-performance camera and sensing system. Its advanced light irradiation technology and image analysis ensure that pack defects are always found.

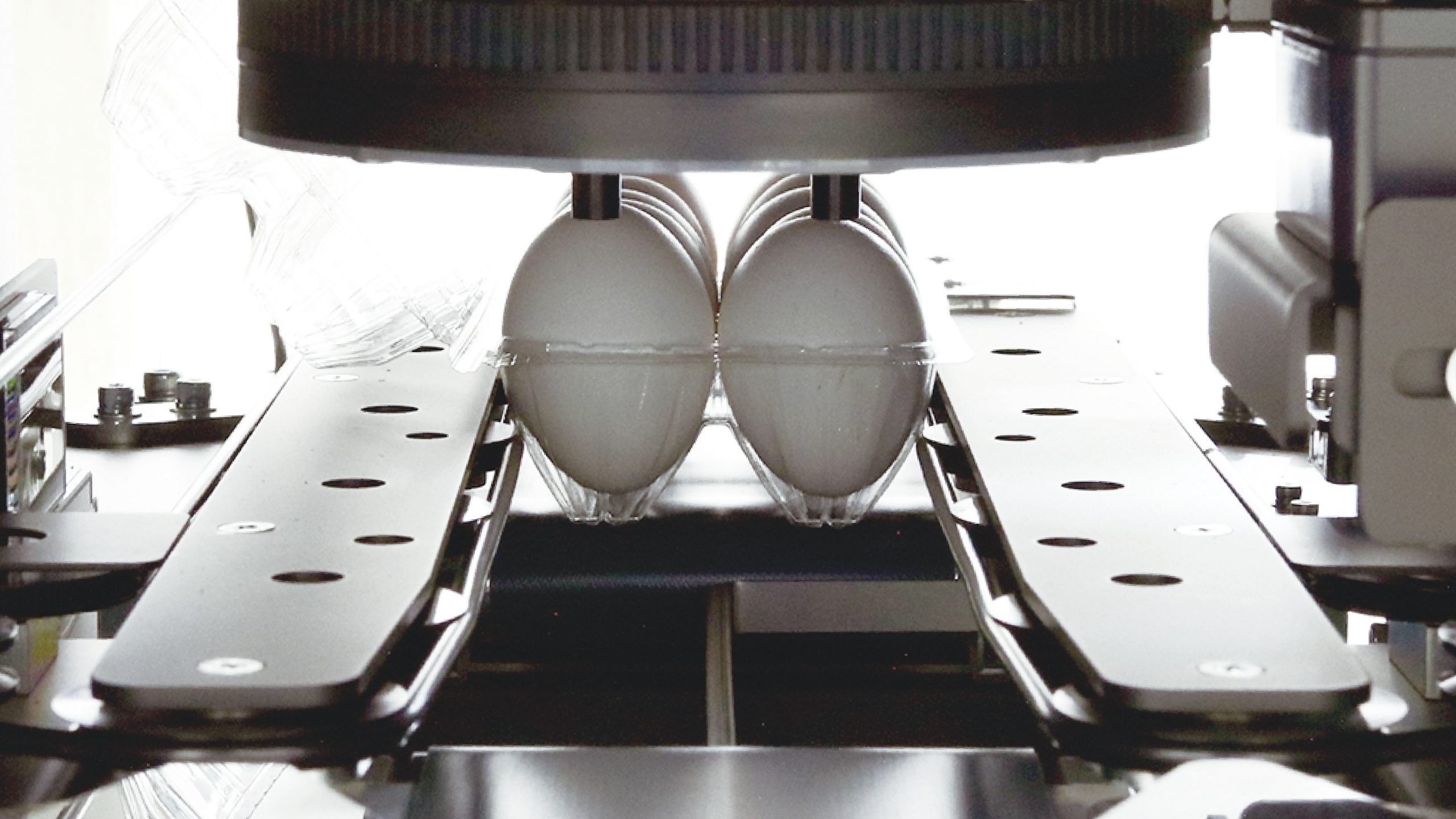

Inspecting the top and bottom of a single pack at once

The specially designed conveyor has an open bottom (bottom-free conveyor) that allows inspection of the top and bottom of a single pack at the same time.

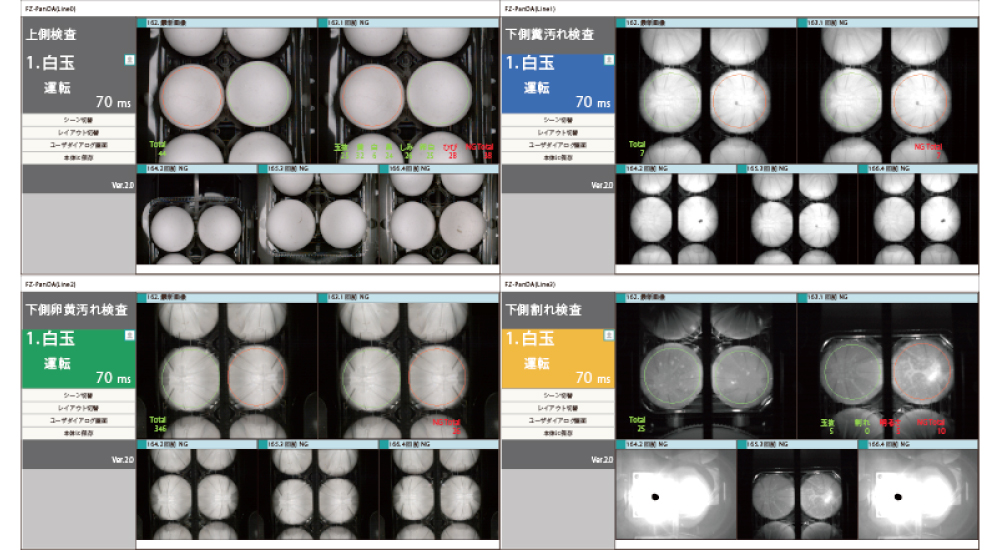

Inspection status displayed in real time

Images of both the top and bottom of a pack are displayed in real time, allowing the user to instantly see the inspection status of unacceptable eggs.

Options

Automatic ejection of NG packs

The Two-Way Sorter separates defective packages from normal ones on the packing line. It removes the defective packages without stopping the packing line.

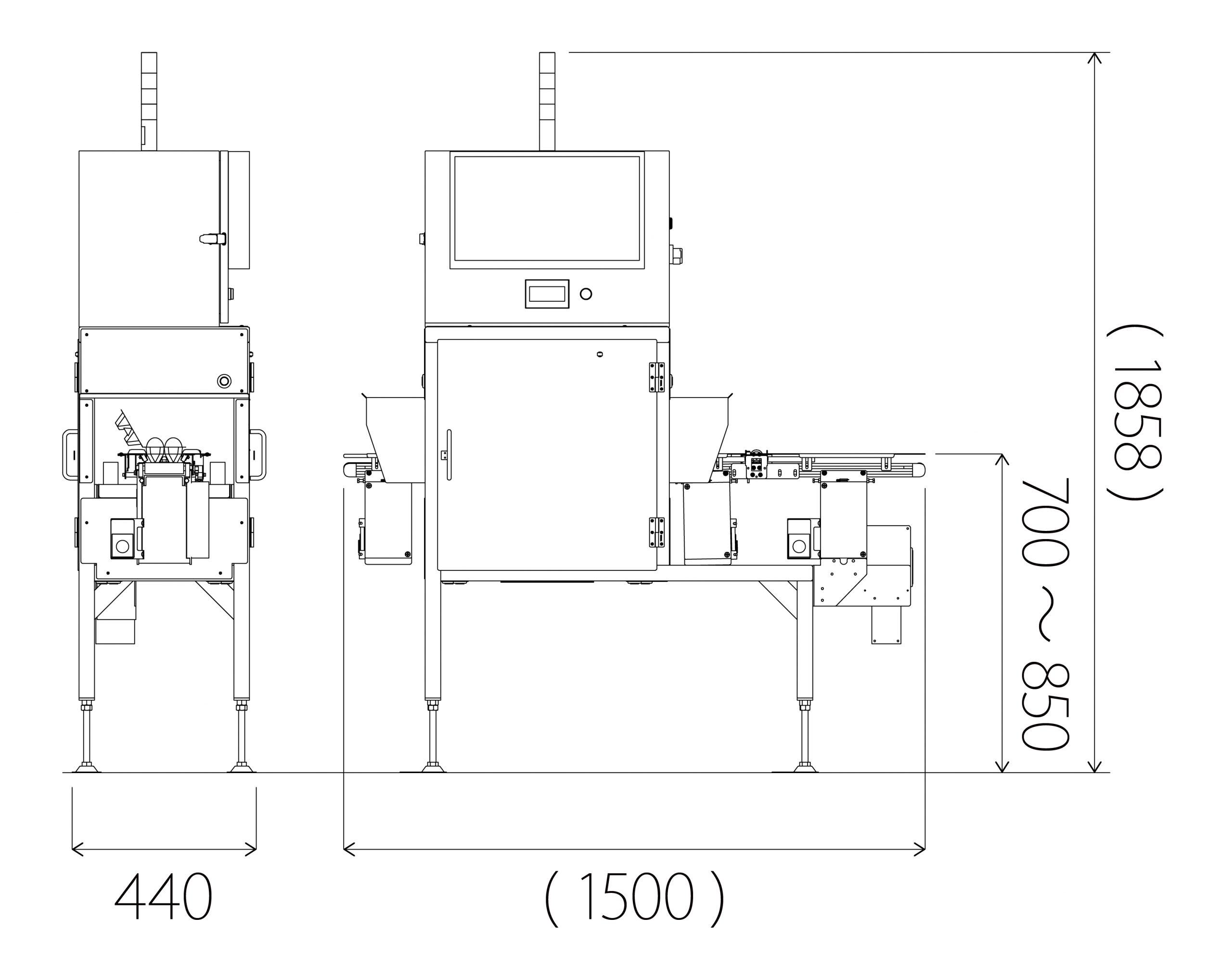

Layout

Specifications

| Code | PAC003 |

|---|---|

| Capacity (Max.) | 40,000 eggs/hr. |

| Power | 1-phase 100V 10.5A |

| Working environment |

Temperature : 10 – 40℃ Humidity : 45 – 80% *1 |

| Available packs | Plastic pack (12P, 10P, 8P, 6P, 4P) *2, 3, 4, 5 |

| Target eggs | Color : White, Red, Pink Size : 2L, L, M, MS, S |

| Conveyor | Speed : 24m/min. ※6 Width : 100mm Height : 700 – 850mm |

*1 No condensation

*2 Compatible with regular and flat packs

*3 For C-NAEGS, SNO, and SNC, only 10P and 6P packs are supported.

*4 Compatible with clear (colorless, pink) plastic packs

*5 Compatible with 2L, L, M, and MS size plastic packs.

*6 The speed of the front conveyor of this equipment shall be less than 21 m/min.

Designs and specifications are subject to change without notice.

*2 Compatible with regular and flat packs

*3 For C-NAEGS, SNO, and SNC, only 10P and 6P packs are supported.

*4 Compatible with clear (colorless, pink) plastic packs

*5 Compatible with 2L, L, M, and MS size plastic packs.

*6 The speed of the front conveyor of this equipment shall be less than 21 m/min.

Designs and specifications are subject to change without notice.