Products

Hatching Egg Grader

Hatching eggs

Alignment, separation, and gentle placement

After correctly orientating hatchery eggs and eggs for vaccine production, the machine sorts them into several grades based on their weight. Each egg is transported using a suction cup that softly places them into the tray. In addition to speeding up operations and reducing manpower and labor through automation, the machine provides a variety of options, such as egg washing and inspection.

Features

High-accuracy weighing and sorting functions

Equipped with a high-accuracy load cell scale, the machine can sort eggs into multiple grades based on weight.

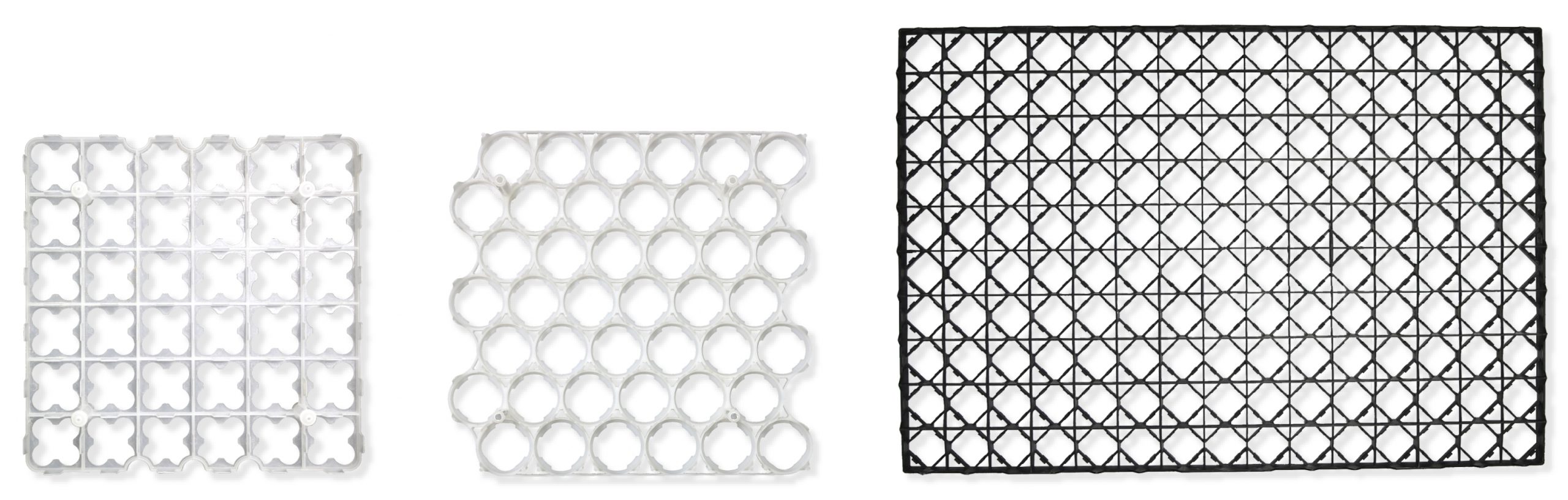

Compatible with various trays

It can flexibly handle setter trays such as 6x6, 6x7 and 10x15 from major incubator manufacturers, as well as 30egg plastic and mould trays, enabling automation of setter filling operations that require human hand.

Setter trays

6×6 / 6×7 / 10×15

A full range of options to meet your needs

We can accommodate various options such as egg washer & dryer and various inspection devices to meet customer needs.

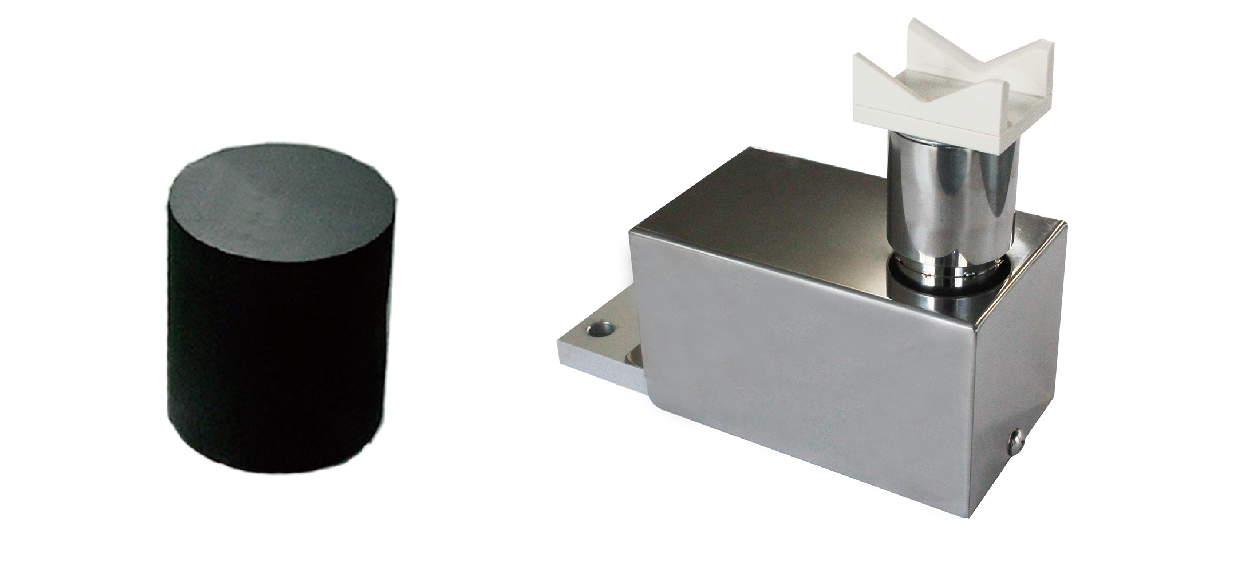

Washer & Dryer

Automatic Crack Detector

Abnormal Egg Detector

Automatic Dirt Detector

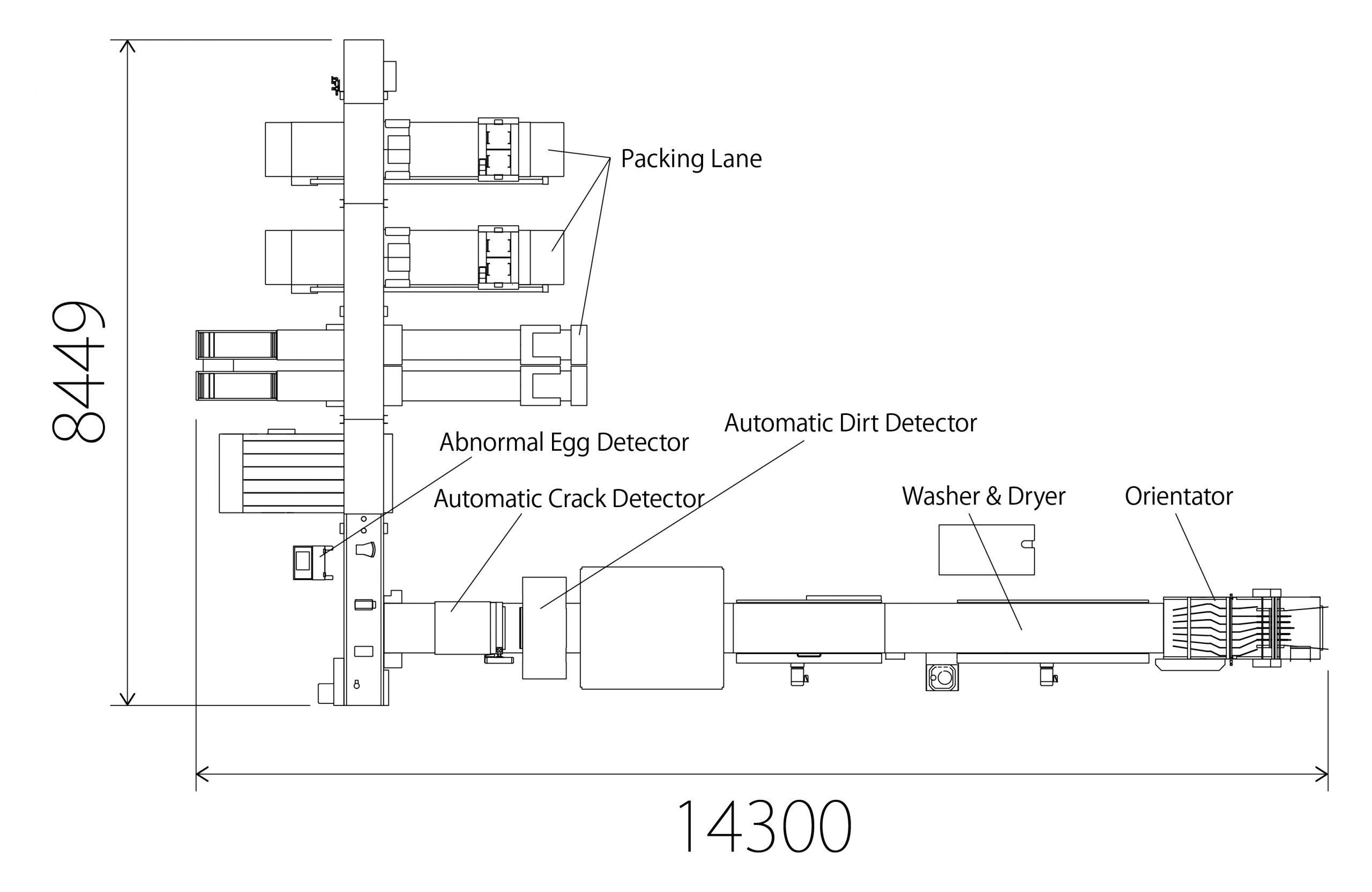

Layout

PEP2000Advance

*This layout is an example.

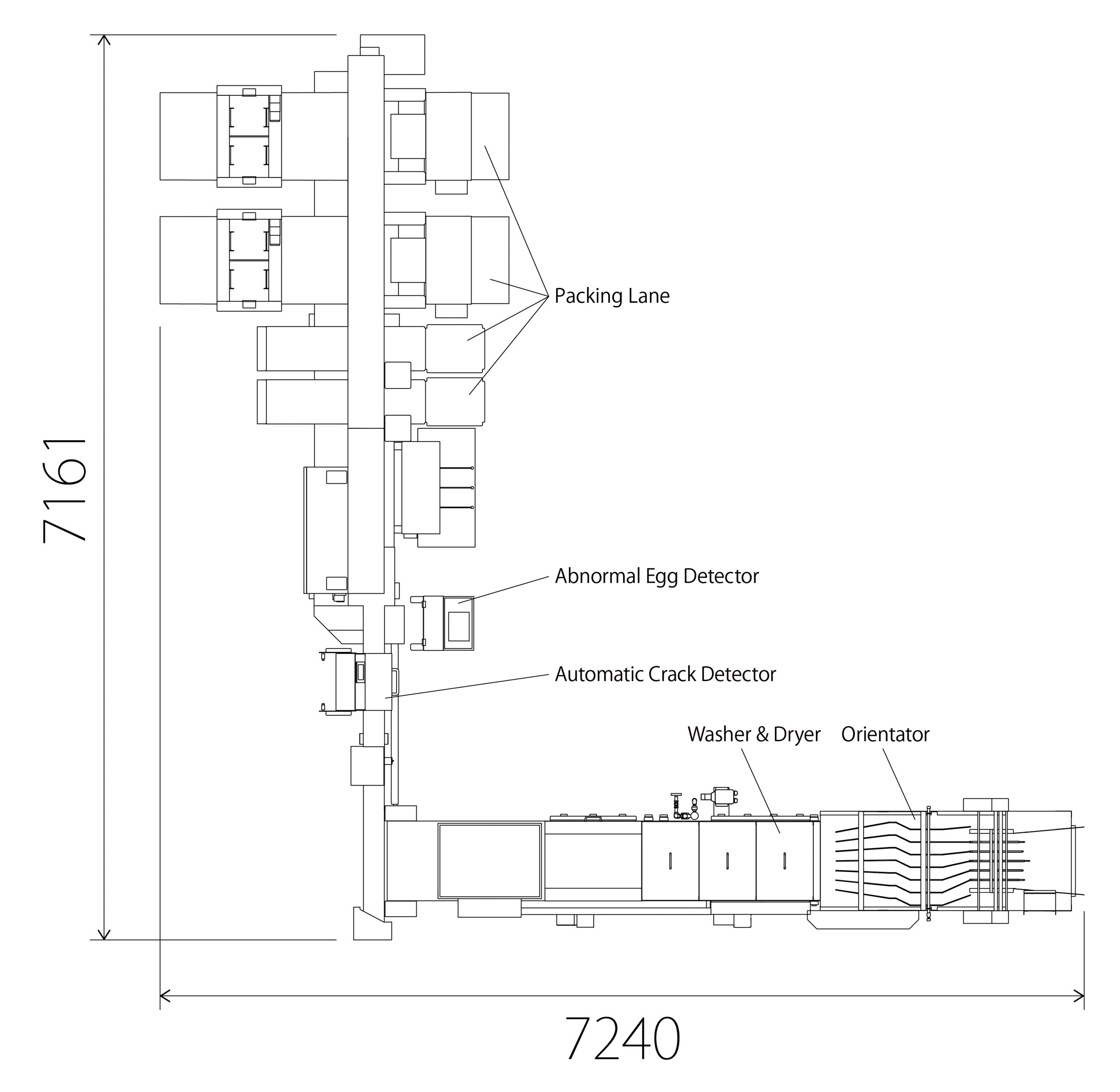

PEP1100

*This layout is an example.

Specifications

| Code | PEP2000 Advance | PEP1100 |

|---|---|---|

| Capacity (Max.) | 20,000 eggs/hr. | 11,000 eggs/hr. |

| Power | 3-phase 200V *1 1-phase 100V *1 |

3-phase 200V *1 |

| Air consumption | 0 – 150L/min. (ANR) ※2 | 0 – 50L/min. (ANR) ※2 |

| Working environment |

Temperature : 0 – 40°C Humidity : 45 – 80% ※3 |

|

*1 Varies according to machine specifications.

*2 This may vary depending on specifications.

The above values do not include any amount consumed in the feeding and candling parts.

*3 No condensation

Designs and specifications are subject to change without notice.

*2 This may vary depending on specifications.

The above values do not include any amount consumed in the feeding and candling parts.

*3 No condensation

Designs and specifications are subject to change without notice.