Products

Palletizer / Depalletizer

Egg collection system

Palletization by robot reduces labor

The Palletizer / Depalletizer can automate the loading and unloading of trays onto and from pallets. The robot also feeds and stacks dividers, freeing operators from heavy labor.

Video

Features

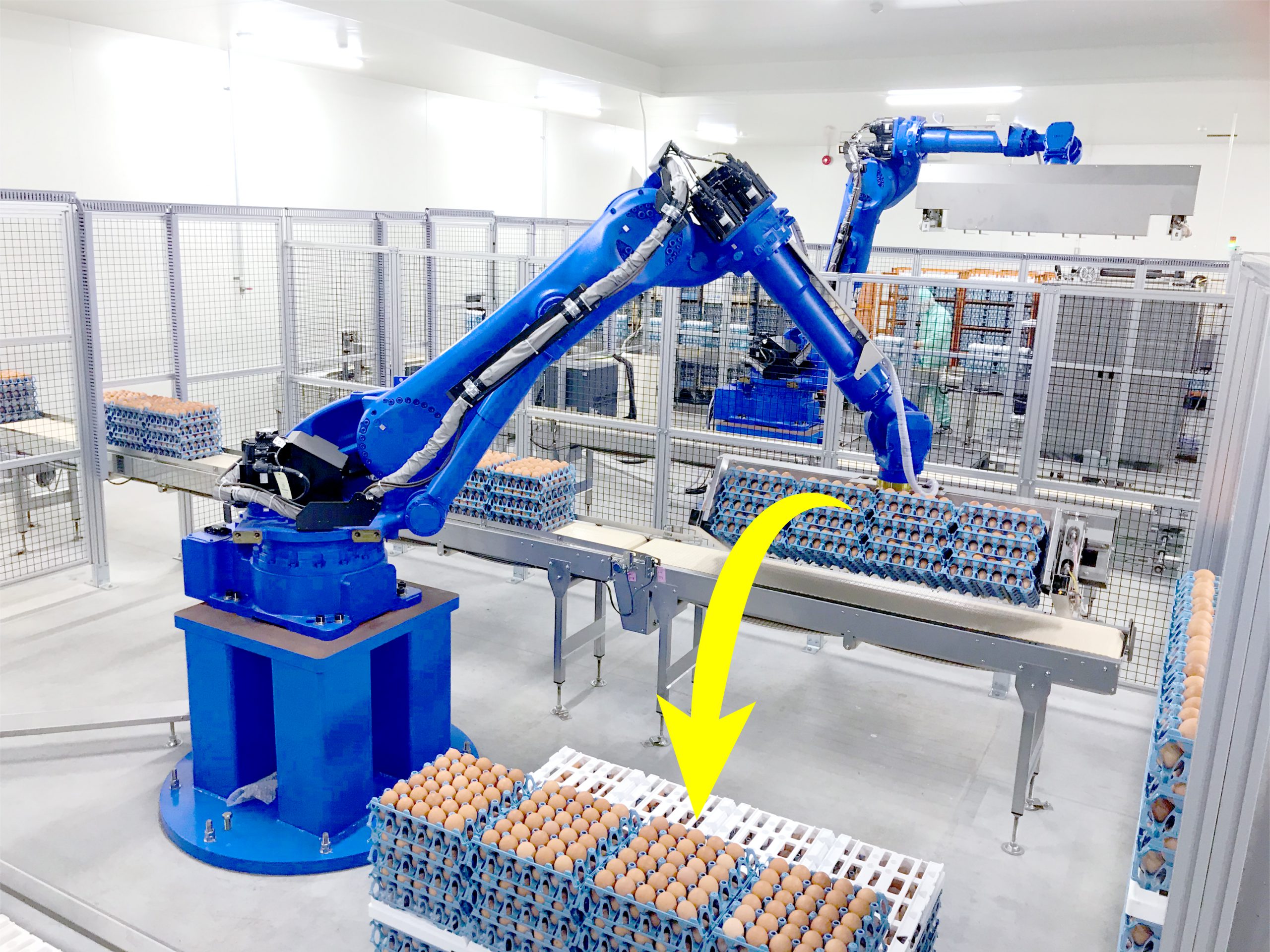

Palletizing

The robot can load four tray stacks at once from the conveyor to the pallet, accommodating up to 12 pallets and 60 dividers.

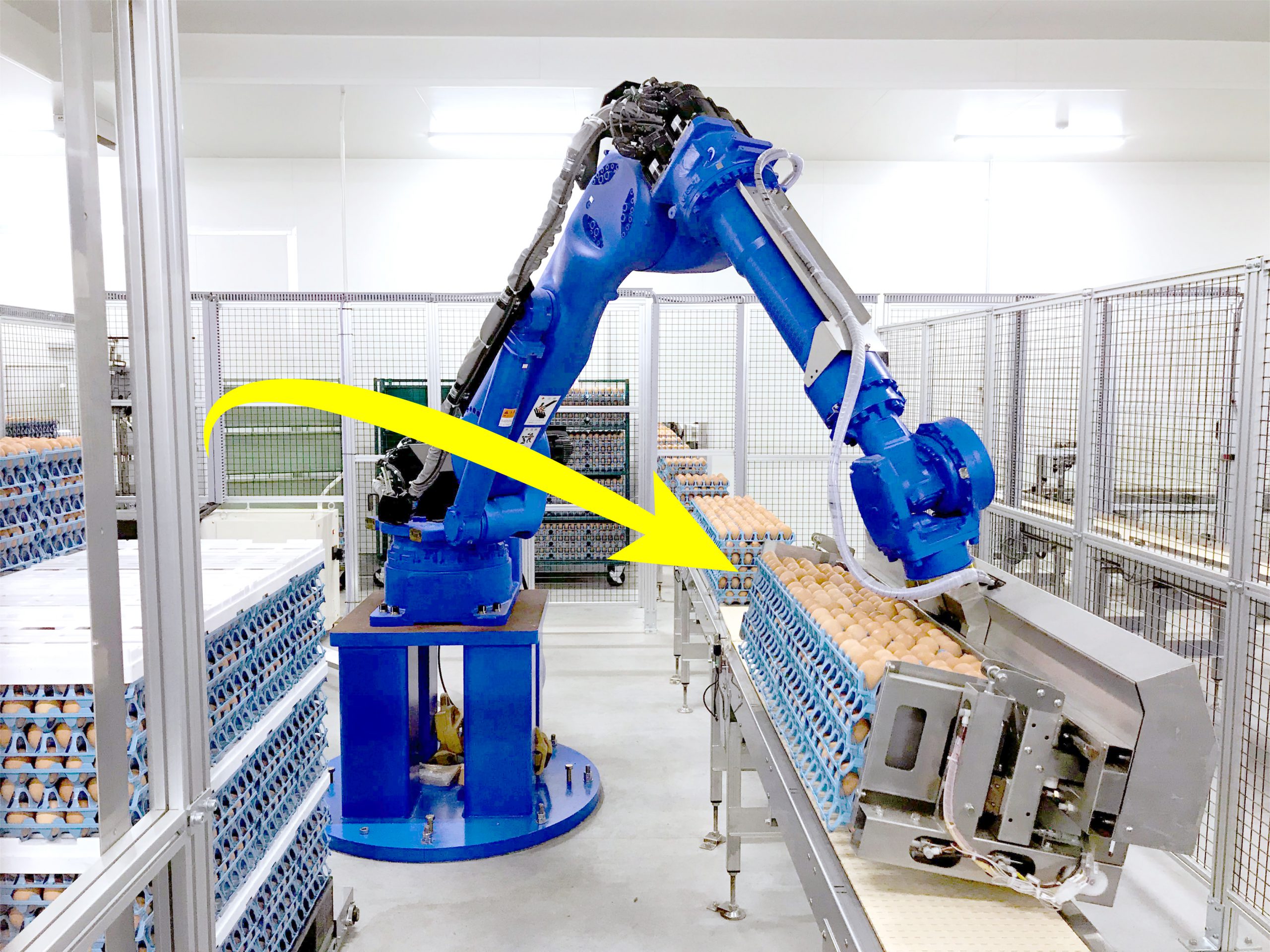

Depalletizing

The robot unloads tray stacks from the pallet onto the conveyor.

It also transfers used dividers and pallets to the loading position.

It also transfers used dividers and pallets to the loading position.

Pallet Transportation System

The system transports eggs using NS-trays, pallets, and dividers.

One pallet can carry up to 12,960 eggs (in the case of six layers of tray stacks).

Linking the system with Palletizer / Depalletizer improves transportation efficiency and saves space in storage areas.

One pallet can carry up to 12,960 eggs (in the case of six layers of tray stacks).

Linking the system with Palletizer / Depalletizer improves transportation efficiency and saves space in storage areas.

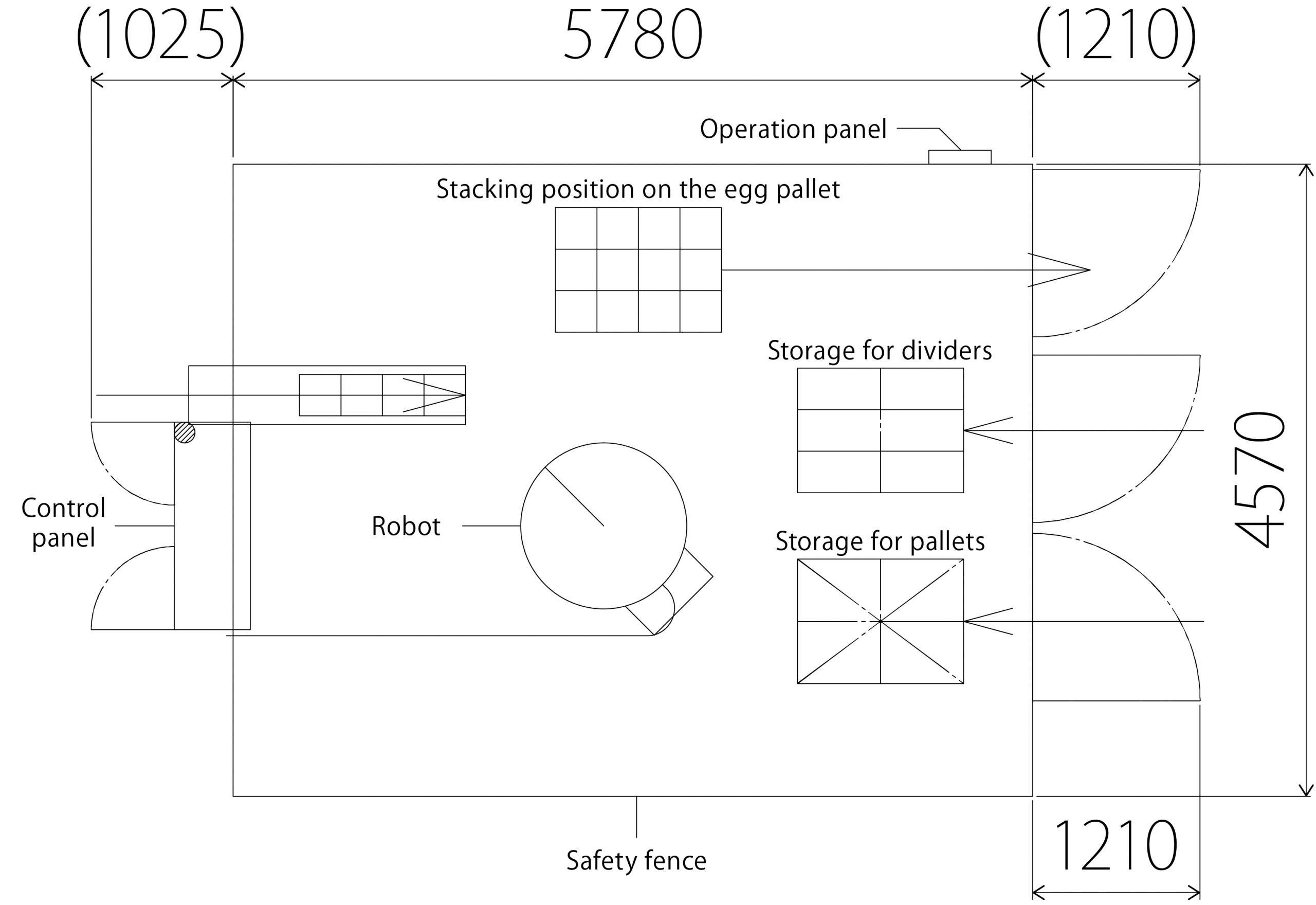

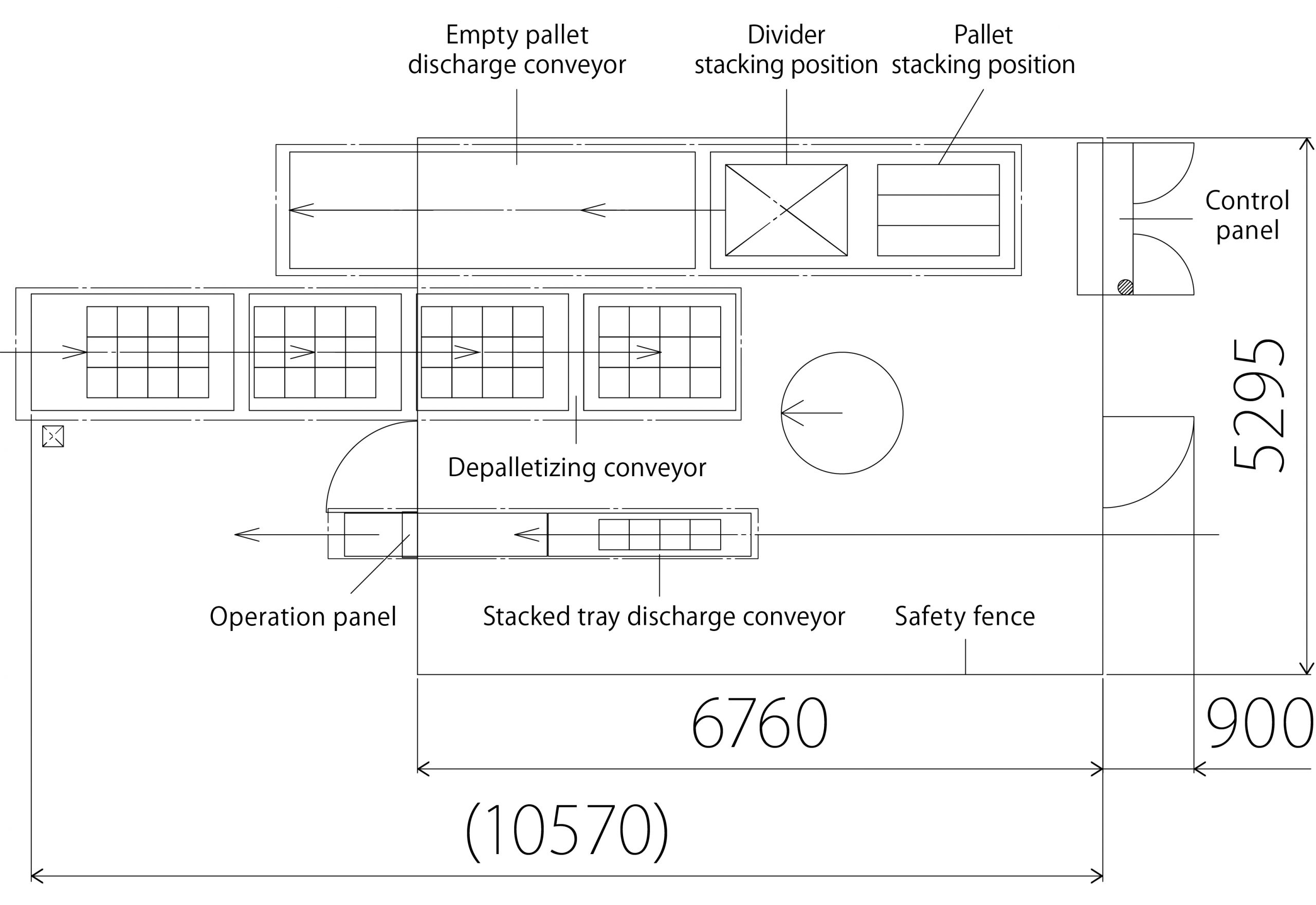

Layout

Palletizer

Depalletizer

Specifications

| Code | PLZ001 Manual discharge |

PLZ003 Automatic discharge |

DPL001 | DPL180 |

|---|---|---|---|---|

| Capacity (Max.) | 120,000 eggs/hr. ※1 | 180,000 eggs/hr. ※1 | ||

| Power | 3-phase 200V 30.0A | 3-phase 200V 40.0A | ||

| Air consumption | 10.8L/min. (ANR) | |||

| Working environment |

Temperature : 0 – 40℃ Humidity : 45 – 80% ※2 |

|||

| Number of dividers stocked (Max.) |

60 pcs | |||

| Numbers of layers on a tray (Max.) |

6 layers | |||

| Available trays | Egg Production Systems Eggs Cargo System |

|||

*1 When stacked in 5 layers

*2 No condensation

Designs and specifications are subject to change without notice.

*2 No condensation

Designs and specifications are subject to change without notice.