Products

Case Palletizer

SMART Cube

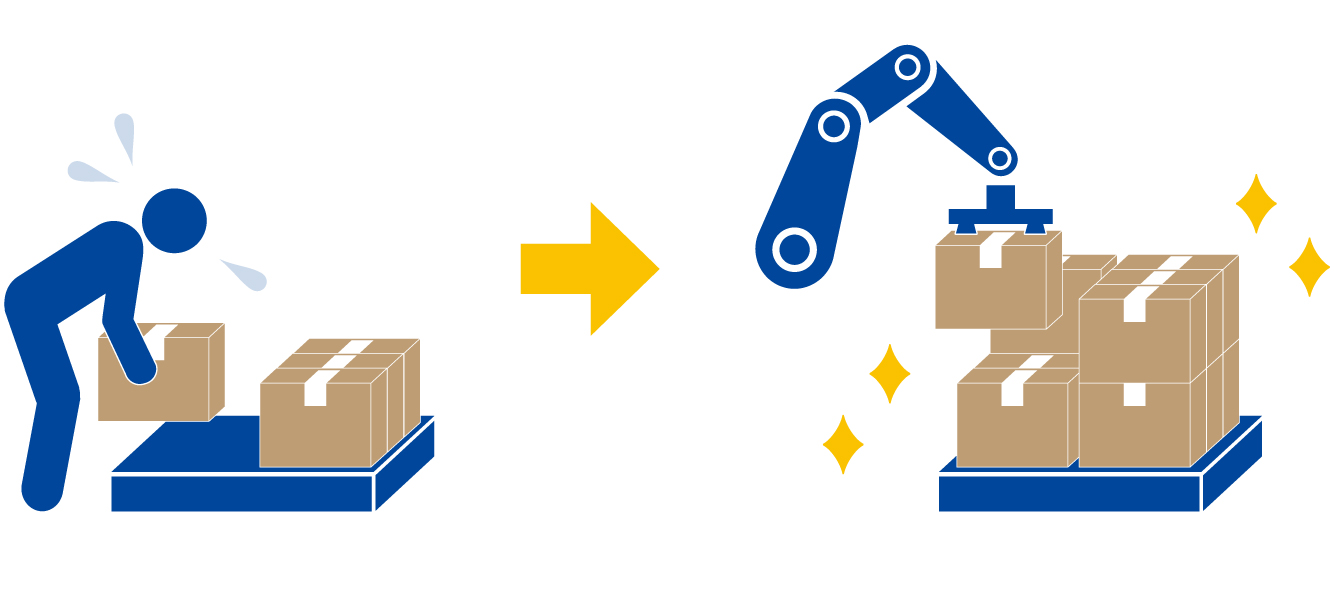

Automated stacking of boxes on pallets

This machine palletizes cartons and containers. It supports more than 10 stacking patterns, allowing for flexible stacking according to the situation. For full automation, our lineup includes models that can automatically discharge completed pallets.

Features

SMART Cube Series

Robots automate operations such as container supply, boxing, box stacking, and pack trolley stacking. Automation of labor-intensive tasks reduces the workload on site. In addition, because the robot performs the work, it is not dependent on the skills of the operator or the speed of the work, and stable performance can be expected.

Reduced workload

The robot effortlessly handles pack-stacking tasks that originally require manpower. High-speed handling takes place at up to 10 seconds per cycle, ensuring stable production on the packaging line.

Compatible with a variety of cases

Cases (e.g. cartons and containers) that flow in from the conveyor are palletized. This series of machines can significantly reduce palletizing labor, the most physically demanding task in the packaging line.

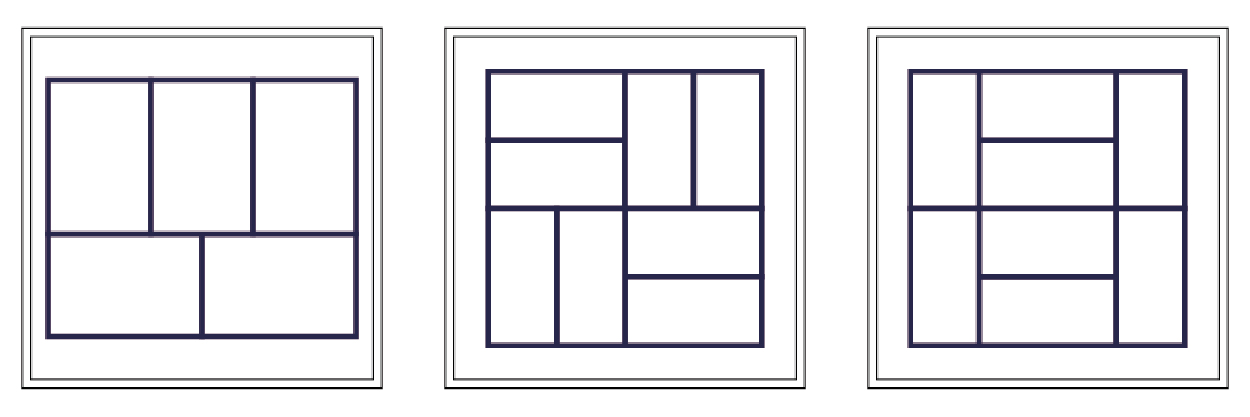

A wide variety of palletization patterns

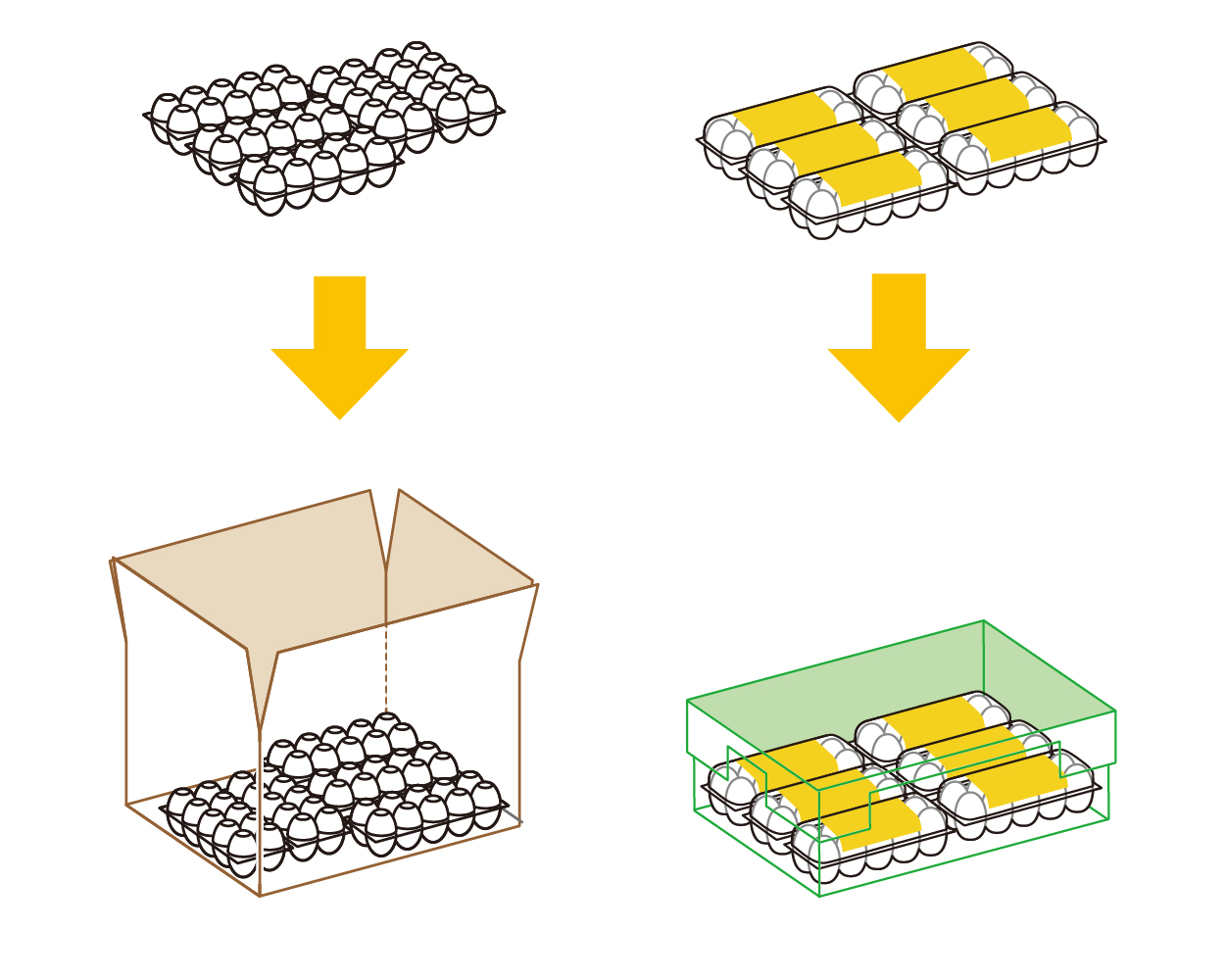

Example of cardboard stacking

A variety of palletization patterns for cartons are supported depending on their types.

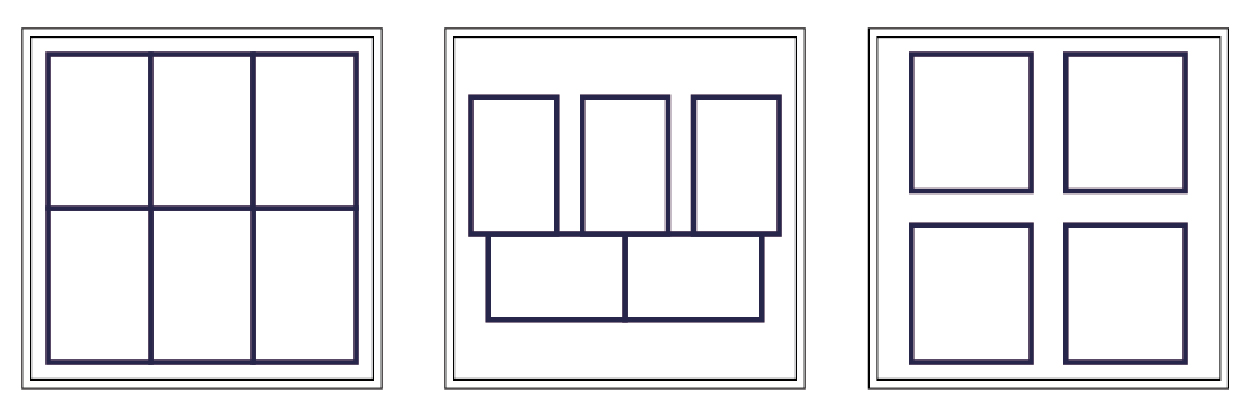

Example of container stacking

A variety of palletization patterns for containers are supported depending on their type.

A lineup to suit your use

We offer two models to suit the needs of user sites: a model with automatic pallet discharge and another with manual discharge.

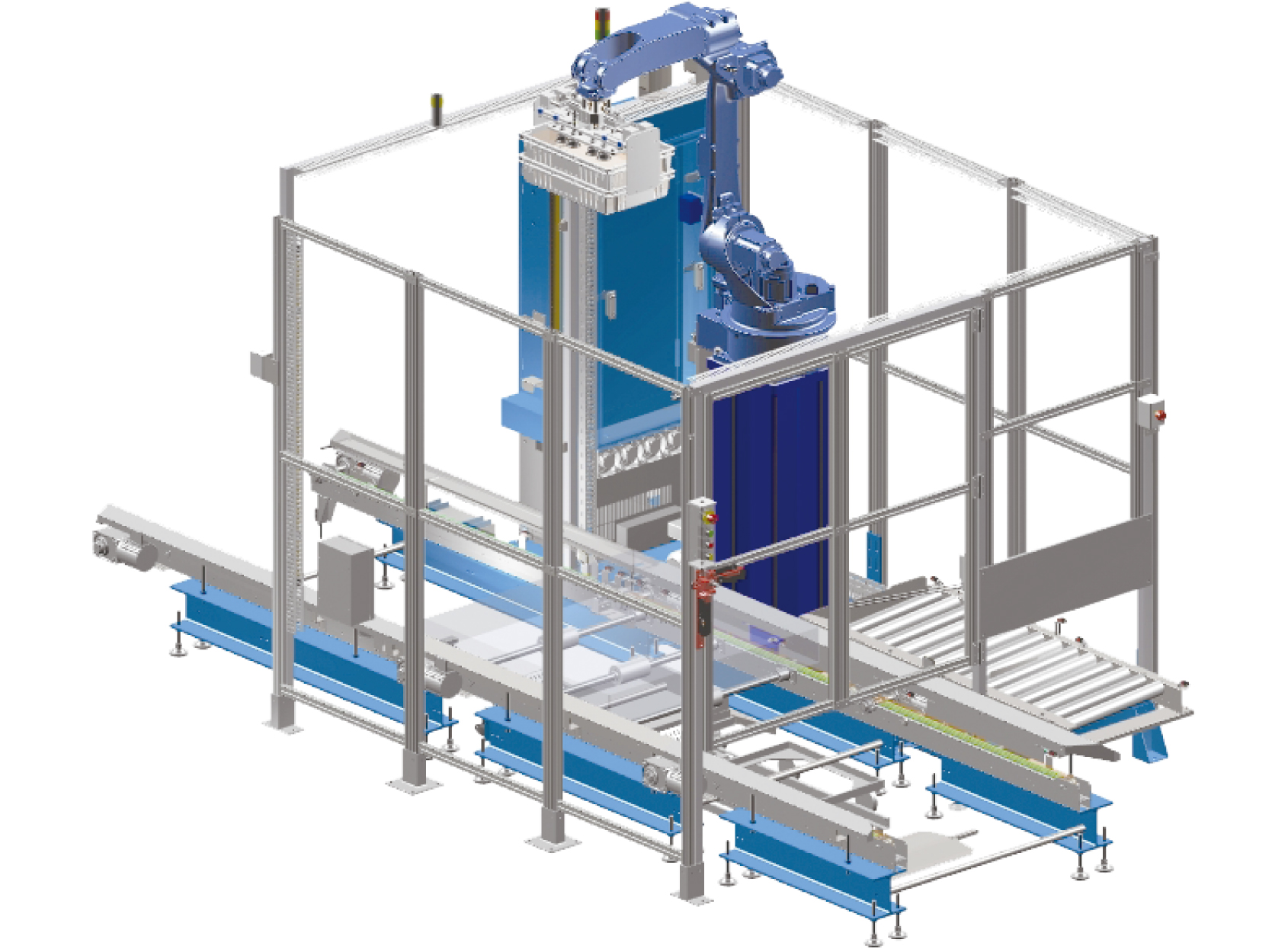

Automatic discharge

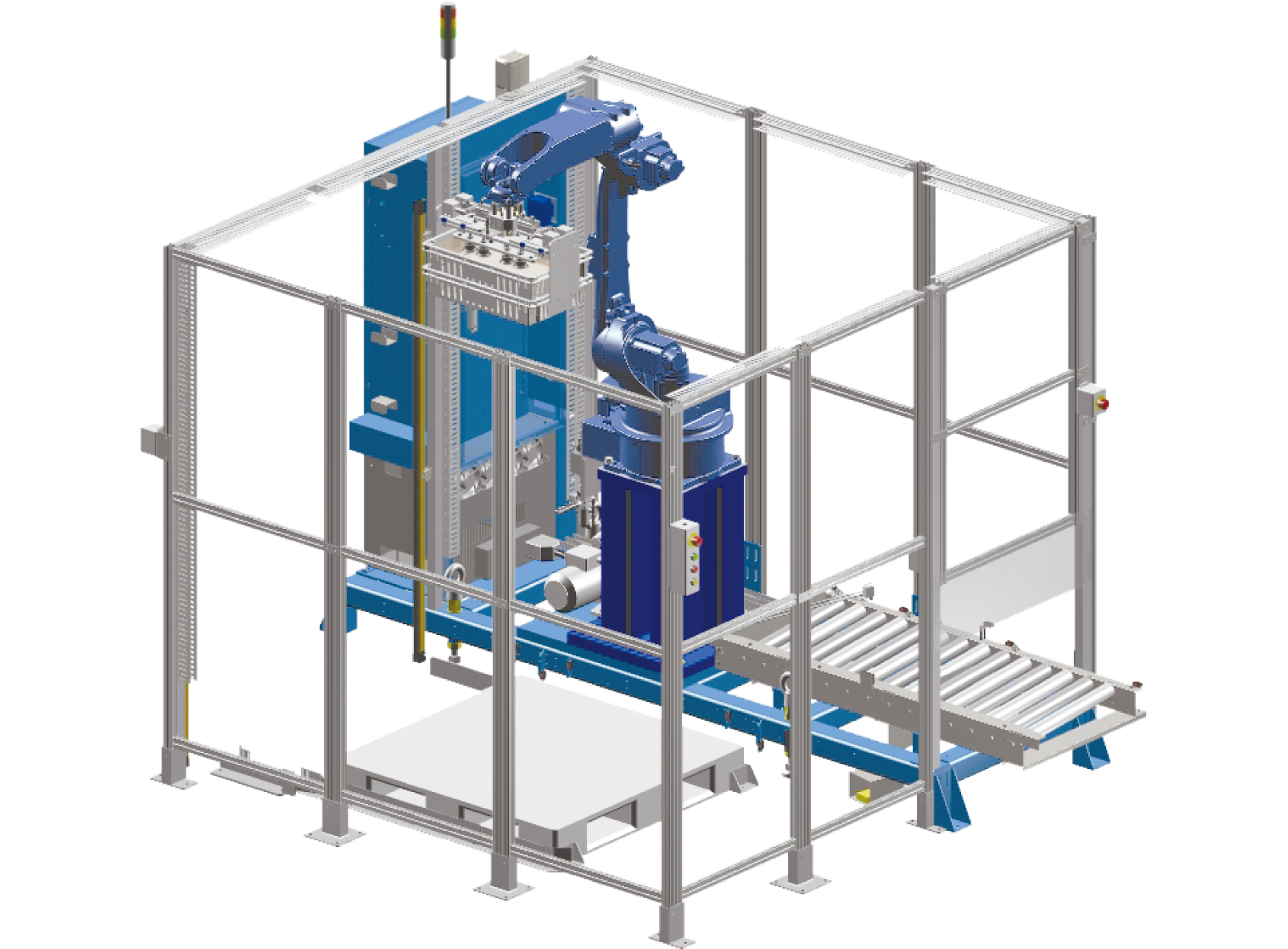

Manual discharge type

Options

Box Printer

This series of machines print dates, including expiration dates, on cartons while they are being transported on the conveyor. Date inspection functions may also be added.

Additionally, we offer a model that prints at the outlet of the carton sealing machine, without a conveyor.

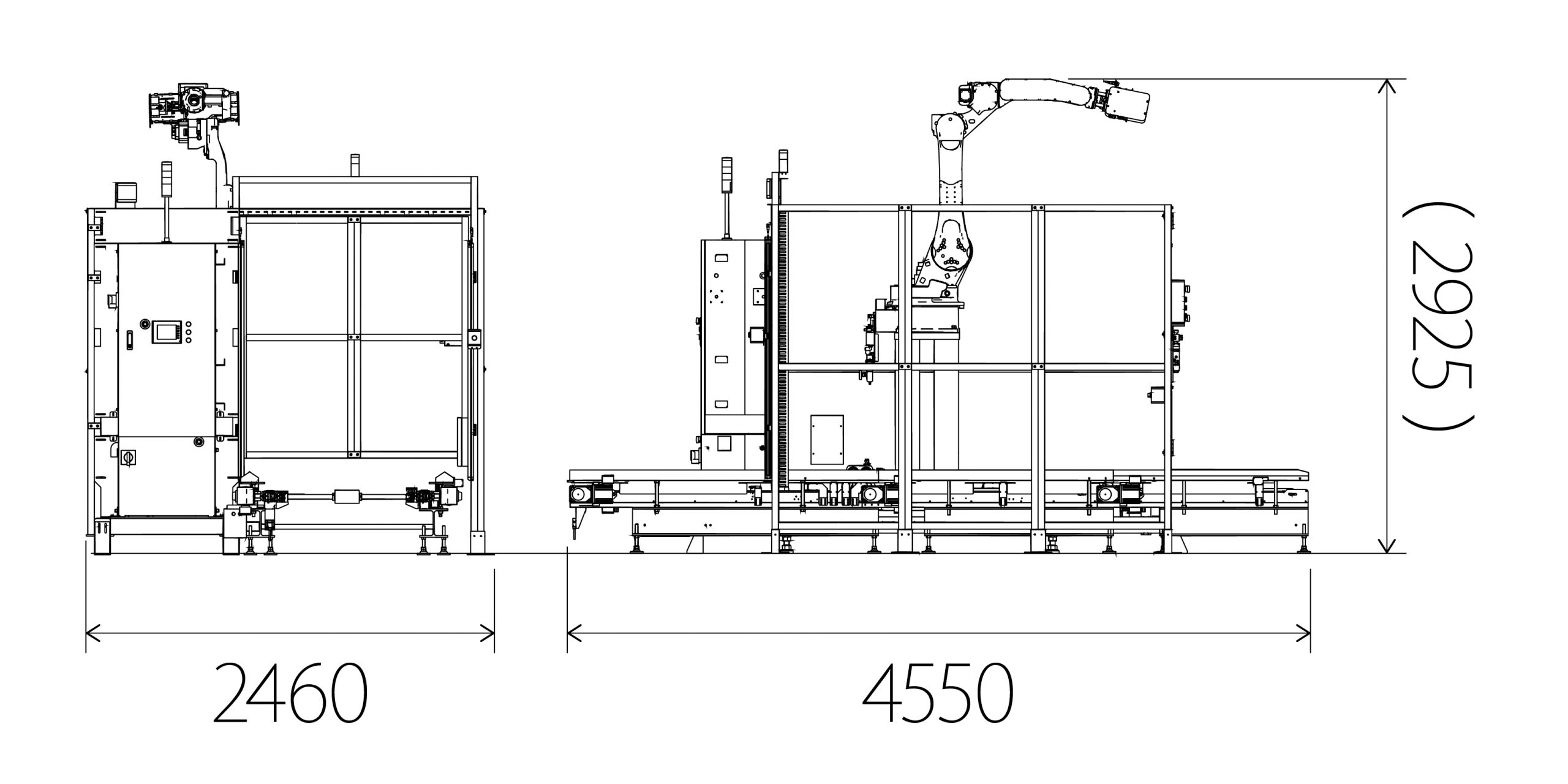

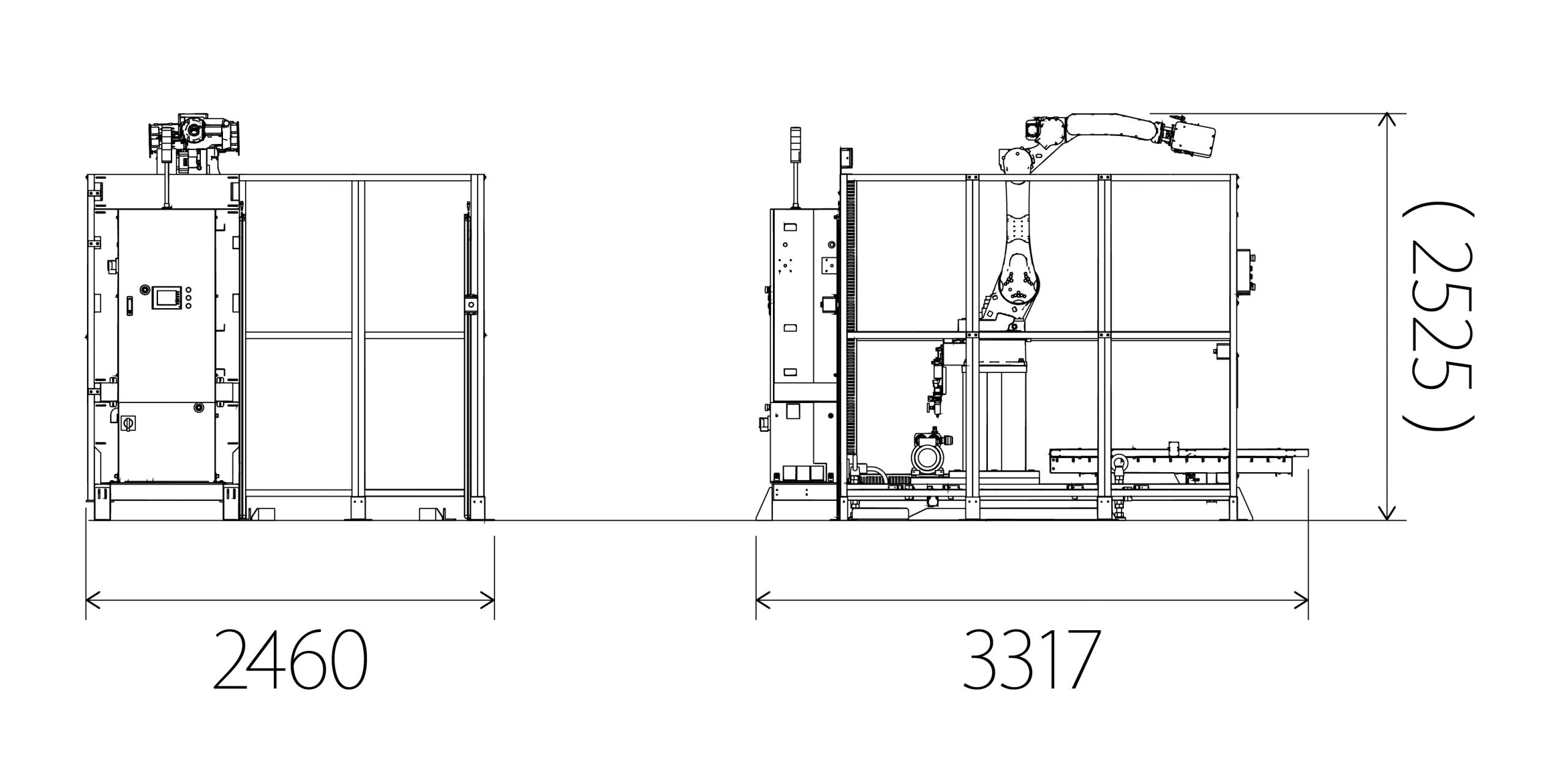

Layout

Automatic discharge type

Manual discharge type

Specifications

| Code | Automatic discharge type | Manual discharge type |

|---|---|---|

| Capacity (Max.) | 43,200 eggs/hr. *1, 2, 3 | |

| Power | 3-phase 200V 23.3A | 3-phase 200V 16.0A |

| Air consumption | 10L/min. (ANR) | |

| Air supply pressure | More than 0.55MPa | |

| Working environment |

Temperature : 0 – 40℃ Humidity : 45 – 80% *4 |

|

| Available cases *5 | Cardboard, Containers | |

| Available pallets *6 | Plastic pallets, Wooden pallets | |

*1 When 10P x 12 packs/case

*2 Depending on the stacking pattern, the capacity of this equipment may be less than that of the repacker.

*3 Processing capacity varies depending on the number of packs filled in a case and the stacking pattern.

*4 No condensation

*5 Only cases that have been tested in our company can be handled.

*6 Width and depth lengths greater than 1200 mm and less than 900 mm cannot be used.

Designs and specifications are subject to change without notice.

*2 Depending on the stacking pattern, the capacity of this equipment may be less than that of the repacker.

*3 Processing capacity varies depending on the number of packs filled in a case and the stacking pattern.

*4 No condensation

*5 Only cases that have been tested in our company can be handled.

*6 Width and depth lengths greater than 1200 mm and less than 900 mm cannot be used.

Designs and specifications are subject to change without notice.