Products

Pack Trolley Loader

SMART Cube

Automated loading of packs onto roll-box pallets

This machine loads packed products into pack trolleys. A variety of stacking methods are supported, depending on the type of pack trolleys and packs used. This model accepts setups involving two pack trolleys and can adjust to complete product loading on two pack trolleys at the same time. This increases efficiency in switching pack trolleys, reducing the burden on operators.

Features

SMART Cube Series

Robots automate operations such as container supply, boxing, box stacking, and pack trolley stacking. Automation of labor-intensive tasks reduces the workload on site. In addition, because the robot performs the work, it is not dependent on the skills of the operator or the speed of the work, and stable performance can be expected.

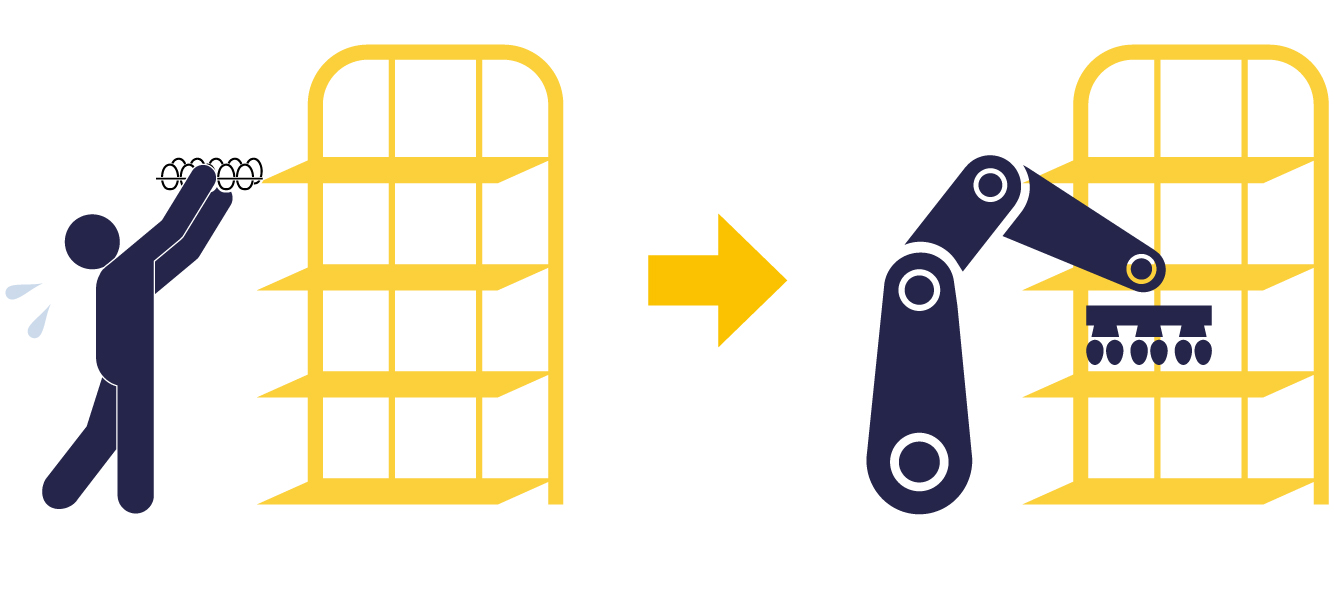

Reduced workload

The robot effortlessly handles trolley-stacking tasks that originally require manpower. It reduces the burden on operators and ensures stable production on the packaging line.

Capable of processing 36,000 eggs per hour

Deployment of one robot for distribution on pack feeding lines and two robots for the process of loading into pack trolleys ensures powerful handling capability that accommodates production volume in upstream processes.

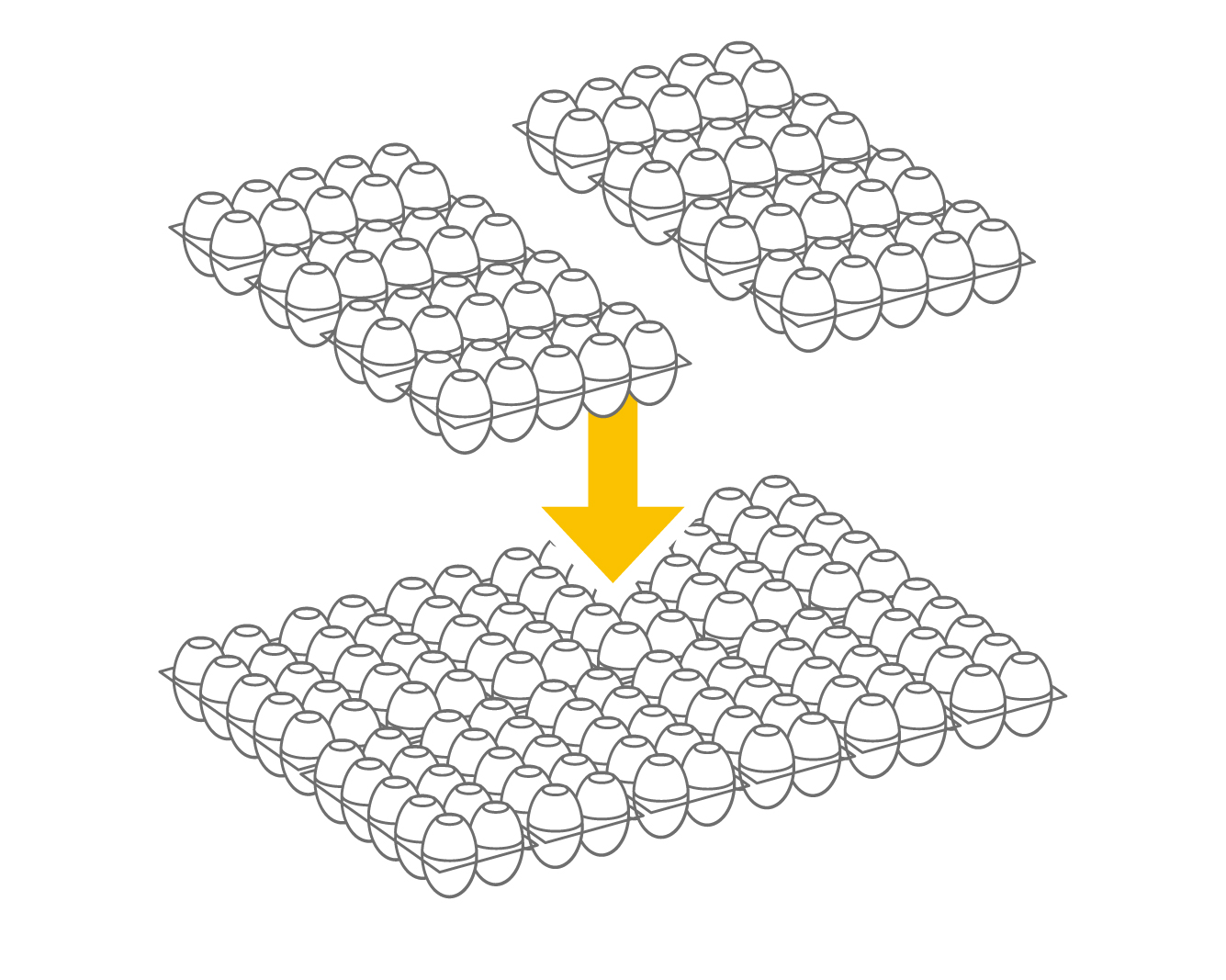

A wide variety of loading patterns

We offer loading patterns that satisfy complex conditions including pack type, number of stacking layers, and number of packs to be loaded. This machine supports a number of loading patterns to accommodate loading onto pack trolleys suitable for each site.

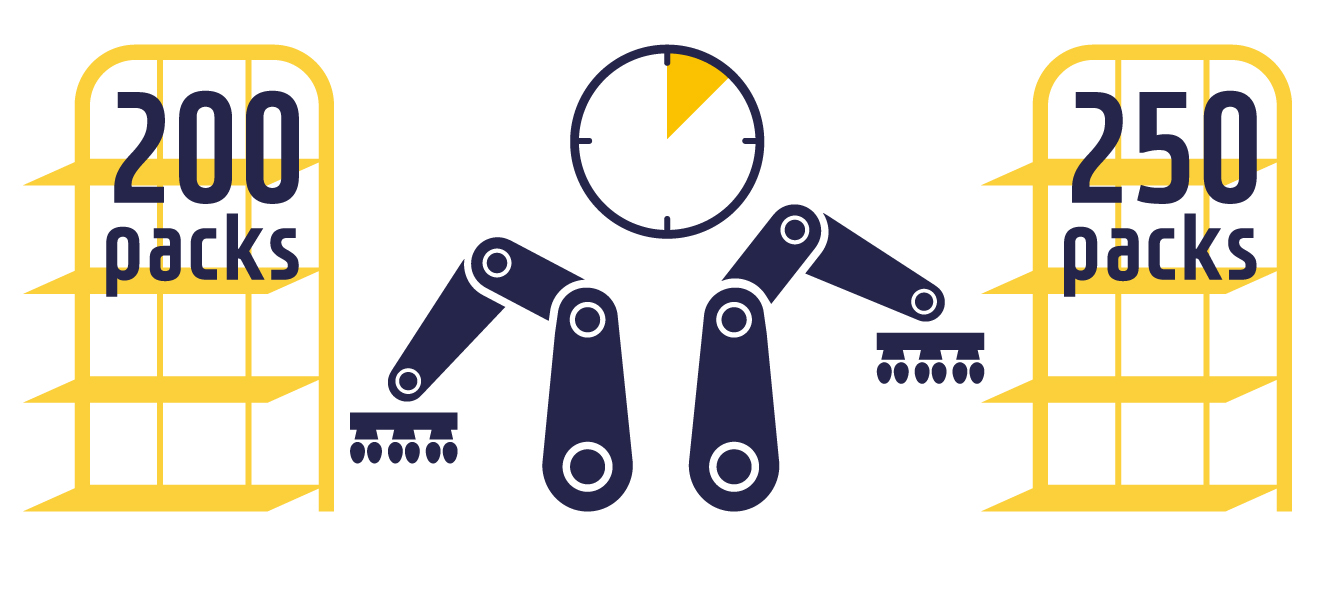

Efficient loading onto pack trolleys using two robots

Even when the loading capacities of the two robots differ, their work speeds are automatically adjusted to allow them to finish loading at the same time. Productivity improves, as pack trolleys can be replaced quickly.

Flexible adjustment functions

Even for the same type of packed product, the amount of packs to be loaded onto each pack trolley can be specified. The order of production according to shipment schedule can also be adjusted with ease. You can also easily switch this order.

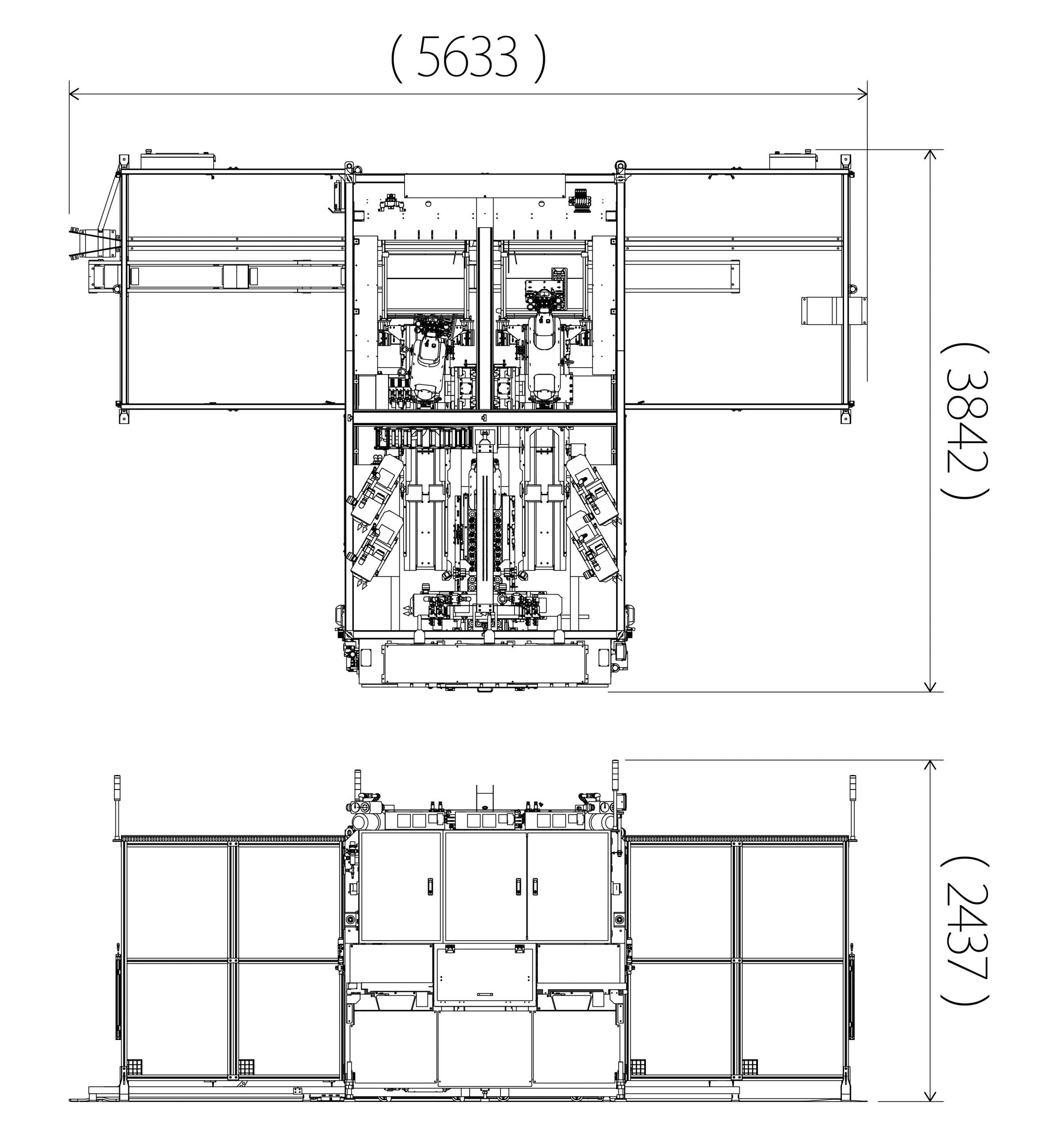

Layout

Specifications

| Code | SRP001 |

|---|---|

| Capacity (Max.) | 36,000 eggs/hr. *1 |

| Power | 3-phase 200V 56.2A |

| Air consumption | 135L/min. (ANR) |

| Air supply pressure | More than 0.5MPa |

| Working environment |

Temperature : 0 – 40℃ Humidity : 45 – 80% *2 |

| Available packs *3 | Plastic packs (10P) *4, 5 |

| Available pack trolleys *6 | KS pack trolleys made by Yoshida-Lsys (4 steps, 3 steps) *7 Pack trolleys made by Sanei Manufacturing (4 steps) Pack trolleys made by Honko Manufacturing (4 steps, 3 steps) |

*1 Processing capacity varies depending on the arrangement of packs in the pack trolley and the number of packs loaded.

*2 No condensation

*3 Only sealed packs can be handled.

*4 Compatible with regular packs, flat packs, and eco-packs

*5 Compatible with 2L, L, M, and MS size plastic packs.

*6 Only pack trolleys that have been tested by us can be used.

*7 Wide type is not supported

Designs and specifications are subject to change without notice.

*2 No condensation

*3 Only sealed packs can be handled.

*4 Compatible with regular packs, flat packs, and eco-packs

*5 Compatible with 2L, L, M, and MS size plastic packs.

*6 Only pack trolleys that have been tested by us can be used.

*7 Wide type is not supported

Designs and specifications are subject to change without notice.