Products

Labeler

Packing

Clear printing and high ink capacity

The labeler prints and applies top labels. For printing, it uses an inkjet mechanism that requires less frequent replacement of ink cartridges than ink ribbon printing, improving productivity.

Features

Built-in inkjet printer

Compared to the ink ribbon type, inkjet printing offers a longer ink life, which reduces the frequency of cartridge replacement.

Print inspector

The print inspector takes the image of a printed top label and instantly analyzes it. In addition to date setting, it can also detect unexpected defects with a high degree of accuracy, such as unclear or blurred printing.

Brush mechanism for horizontal application

The labeler is equipped as standard with a horizontal brush to apply labels neatly and wrinkle-free to the side of the pack.

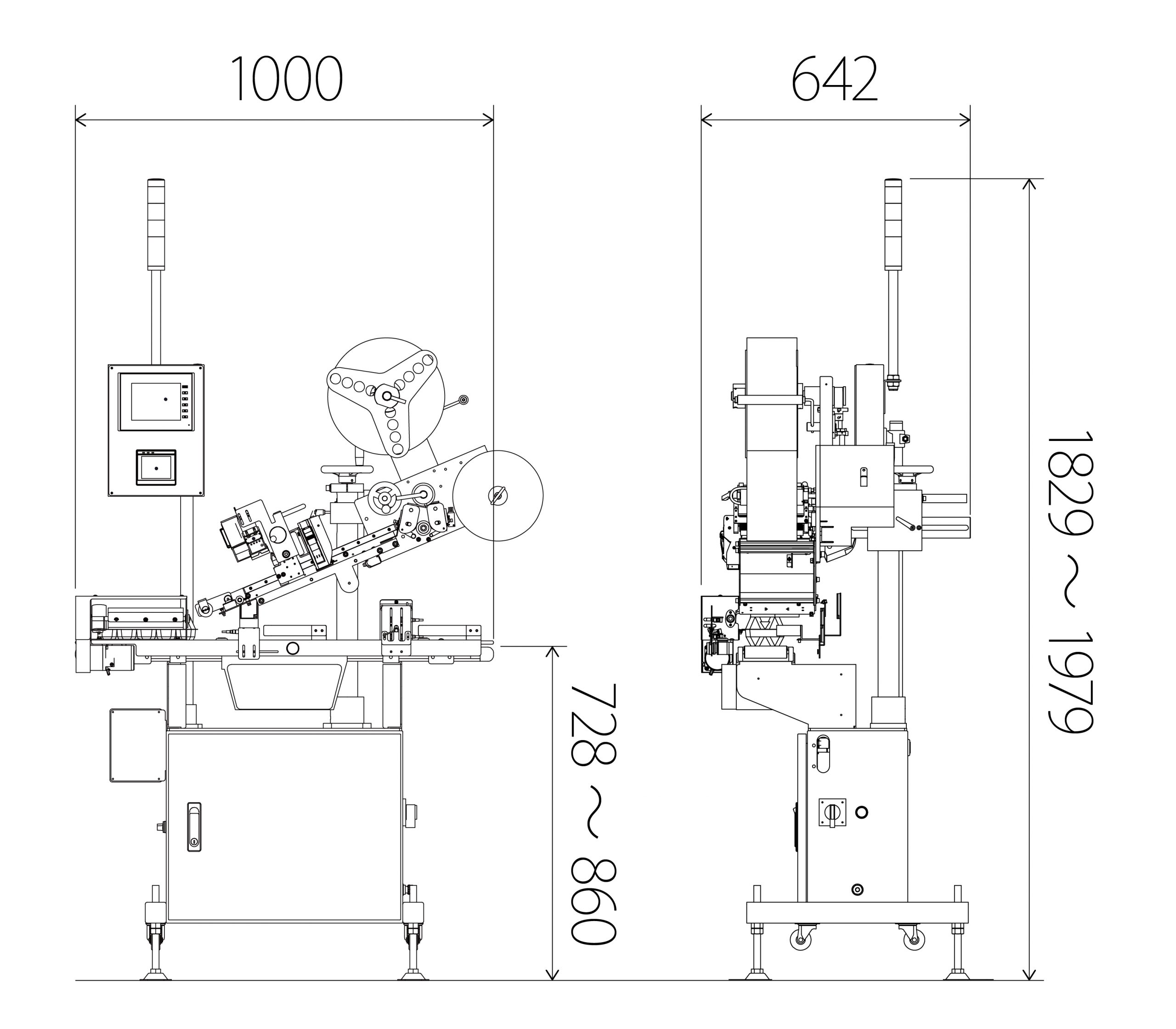

Layout

Specifications

| Code | UBR003 |

|---|---|

| Capacity (Max.) *1 | 12P : 3,750 packs/hr. 10P : 4,500 packs/hr. 8P : 5,625 packs/hr. 6P : 7,500 packs/hr. 4P : 11,000 packs/hr. |

| Power | 1-phase 100V 8.7A |

| Working environment |

Temperature : 15 – 35℃ Humidity : 45 – 80% *2 |

| Conveyor speed | 21 m/min. |

| Available packs | Plastic pack (12P, 10P, 8P, 6P, 4P) |

| Number of patterns | 99 |

| Available labels | Width : 30 – 120mm Length : 60 – 300mm Spacing : More than 3mm |

*1 When conveyor speed is 21 m/min.

*2 No condensation

Designs and specifications are subject to change without notice.

*2 No condensation

Designs and specifications are subject to change without notice.