Products

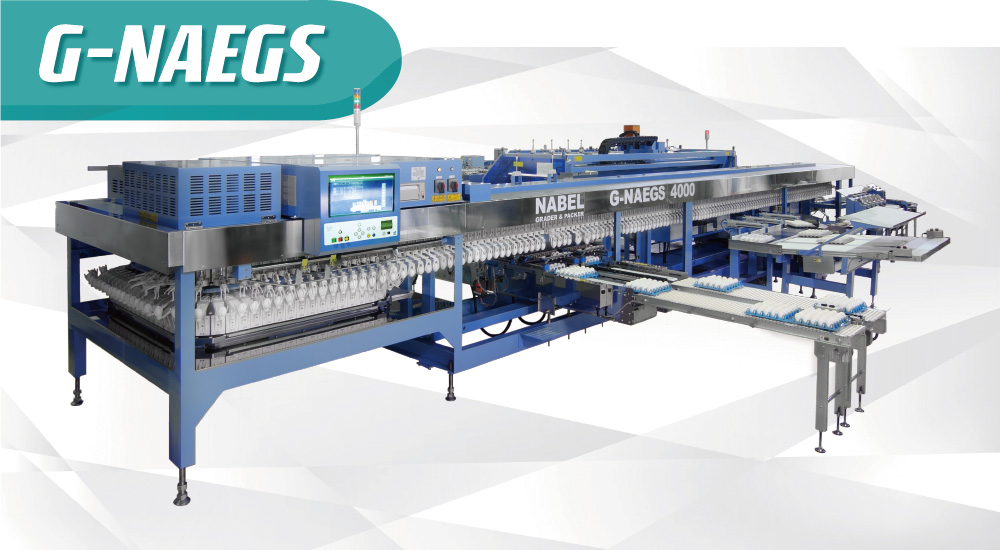

G-NAEGS

Robot System

Robot System G-NAEGS

NABEL's technology and experience are all poured into the G-NAEGS series. A choice is made among three capacity levels of 30,000 / 35,000 / 40,000 eggs per hour. The unique feature of NAEGS is the separation of grading and packing processes. The packing process has become completely independent from washing, drying and grading. This limits an operational loss. When changing the package and label types, make a temporary stop in the packing lines. Washing, drying and grading still continue operating and the eggs get loaded to the stocker. It is space-saving with the 30% greater capacity and only requires few workers.

Features

Faster and safer

G series controller is run by a reliable single chipboard computer. It is an assuring system designed to prevent possible technical troubles. High speed robot enables "Double packing line type", which allows setting 2 packing lines. It is capable of multiple product handling with different containers, stickers and labels. Switching product types is easy and simple; turn off the feeding button of the particular packs, which are no longer necessary. NABEL's NAEGS robot allows continuous small batch production for a wide product range.

Specifications

| Code | G-NAEGS4000 | G-NAEGS3500 | G-NAEGS3000 | |

|---|---|---|---|---|

| Capacity(Max.) | 40,000 eggs/hour | 35,000 eggs/hour | 30,000 eggs/hour | |

| Power required | Power capacity(Max.) | 3-phase 200V 75A*1 1-phase 100V 20A*2 |

||

| Air volume | 50~100L/min(ANR) | |||

| Hot water volume | 10L/min or over (60℃) | |||

| Water volume | 10L/min (200KPa)*3 | |||

| Container | Plastic pack | 5×2 3×2※4 4×2※4 6×2※4 | ||

| Pulp-mold tray | 5×8 5×9 6×9 6×5※4 | |||

| Plastic tray | 6×5 | |||

| Pulp-mold pack | 5×2 6×2※5 | |||

| Functions | Cassette type automatic feeder (4 sizes)*6 | |||

| Automatic feeder for pulp-mold trays (3 size) | ||||

| Automatic feeder for plastic 30-egg trays | ||||

| Automatic label feeding (4 sizes)*6 | ||||

| input and turnover printing | ||||

| Optional devices | Accumulator, Auto Loader, Chemical concentration adjuster, Multi-layer Egg Washer, Automatic Foamer, Automatic Dirt Detector, Automatic Crack Detector, UV Sterilizer, Abnormal Egg Detector, Feeder for specially designed packs, Carrier Washer, Fixed-weight packer program, Production indicator program*7, Repacking function*8 |

|---|

*1 Neccessary if all the above devices are used

*2 Fo product lines

*3 Neccessary if Automatic Foamer (optional) is used

*4 optional

*5 Compatible with carrier to exit robot system

*6 Installation up to five units

*7 Function for producing packs

*8 Packing function for eggs on trays

Designs and specifications are subject to change without notice.

NAEGS stands for NABEL Efficient Grading System.

It is a term coined by NABEL upon the separation of grading and packing for the first time in the world.

*2 Fo product lines

*3 Neccessary if Automatic Foamer (optional) is used

*4 optional

*5 Compatible with carrier to exit robot system

*6 Installation up to five units

*7 Function for producing packs

*8 Packing function for eggs on trays

Designs and specifications are subject to change without notice.

NAEGS stands for NABEL Efficient Grading System.

It is a term coined by NABEL upon the separation of grading and packing for the first time in the world.

Optional Equipment

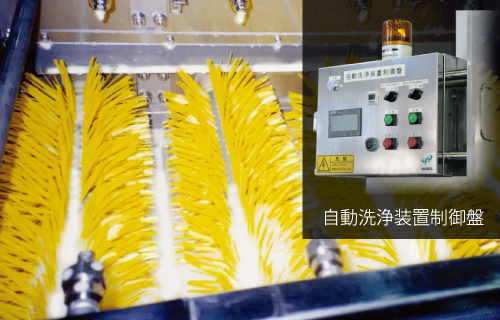

AWU330 Automatic Foam-washer

Daily cleaning which involves detachment of brushes from the washer and dryer can be hard work. The automatic foamer projects detergent foam, rinses and dries the whole interior of the machine as well as the brushes all automatically. This takes only 30 minutes. The supplementary hose allows cleaning specific spots.

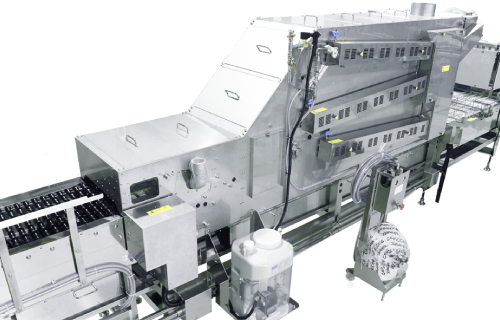

WWW4000 Multi-layer Washer

Making eggs even cleaner while keeping gentleness to them... NABEL's solution for this is the "multi-layer".

Eggs literally go zigzag inside the machine so the washing process becomes longer. The number of brushes used is doubled and the washing capability has improved. The installation space and hot water volume consumption do not change from the existing models. A lower ratio of dirty eggs means more profit for customers.

Eggs literally go zigzag inside the machine so the washing process becomes longer. The number of brushes used is doubled and the washing capability has improved. The installation space and hot water volume consumption do not change from the existing models. A lower ratio of dirty eggs means more profit for customers.

BSB101 Remote Control Panel

It can be a nuisance just to walk all the way to the control panel from somewhere distant. BSB101 gives the right solution. It has a set of casters to move easily. By locating it wherever favorable, it is possible to operate while seeing the actual products.